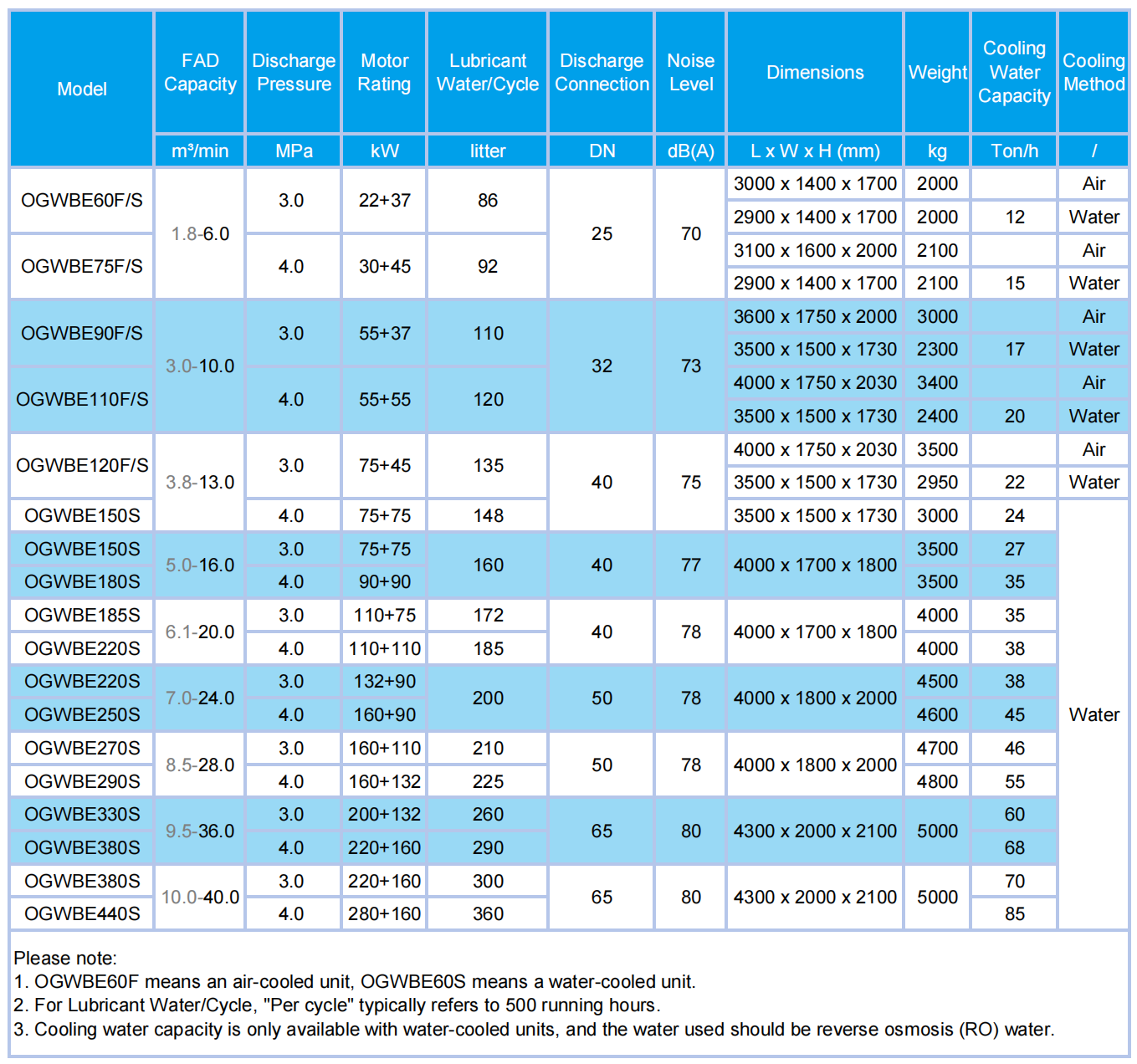

Two Stage Variable Speed Water Injected Oil-Free Screw Compressor Model: OGWBE

- Discharge Pressure: 30-40 [bar], 435-580 [psig]

- Free Air Delivery: 6.0-40.0 [m³/min], 212-1412 [cfm]

- Rated Motor Power: 59-440 [kW], 79-589 [hp]

- Features

- Technical Specifications

- Configuration

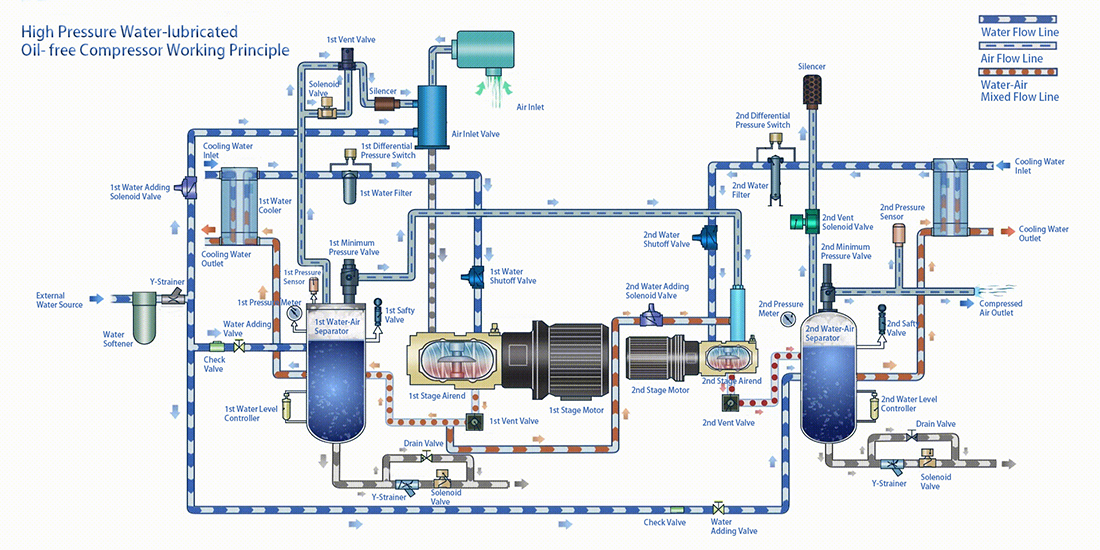

- Schematic Diagram

- Downloads

100% Oil-Free Operation

The compressor uses water for lubrication instead of oil, ensuring 100% clean and pure compressed air that meets ISO 8573-1 (2010) and TÜV CLASS ZERO standards.

High Efficiency

- Single-Screw Technology: Eliminates clearance volume, improving performance.

- Water Lubrication: Seals gaps in the compression chamber, allowing for high efficiency even at temperatures close to 50°C.

- Near Isothermal Compression: Uses water as a cooling medium to maintain constant air temperature throughout compression, reducing energy consumption.

Low Noise

- Quiet Design: Single screw airend utilizes a stainless steel screw rotor and polymer-made star wheels for meshing components.

- Direct Coupling: Features a direct coupling between the motor and the screw, minimizing vibration and noise.

- Sound Insulation: The enclosure is lined with sound-absorbing material to effectively reduce noise levels.

Energy Saving

- VSD+PM Motor: 2 Variable speed drives combined with 2 permanent magnet motors for exceptional energy efficiency and savings.

Stable Air Delivery

- Dynamic Pressure Control: The controller continuously monitors discharge pressure using the compressor’s pressure sensor and adjusts the inverter’s output frequency to regulate motor speed and ensure stable free air delivery.

Robust Components

- Stainless Steel 304: All piping and key components, including the airend (rotor and housing) that come into contact with air and water, are constructed from durable Stainless Steel 304. This ensures long-lasting performance and resistance to corrosion.

OGWBE Model Configuration

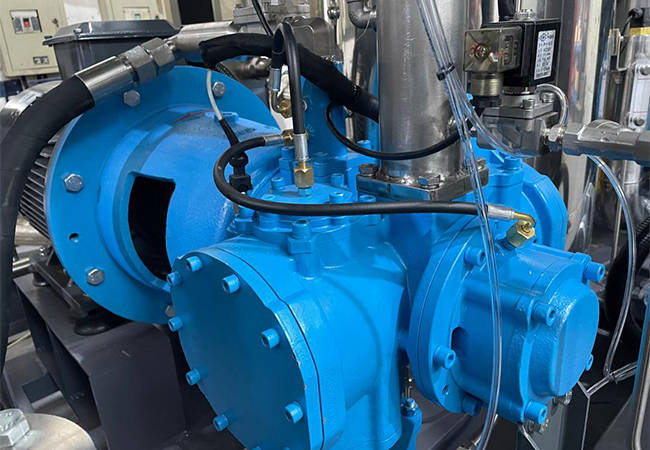

Gairs Airend

- Stainless steel 304 rotor & housing

- Star wheel pieces material: PEEK (polyether ether ketone)

- Speed of Revolution: 3000 rpm

Permanent Magnet Motor

- Motor Enclosure Protection: IP55

- Energy Efficiency Class: IE5

- Direct coupling

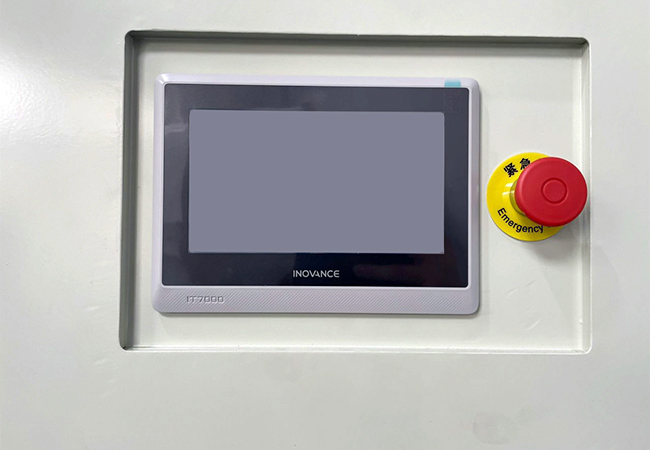

Inverter & PLC controller & HMI Panel

- Brand: Inovance

- Language: Chinese, English, Korean, Russian

Centrifugal Fan (air-cooled unit)

- Enhanced cooling efficiency

- Reduced noise levels

Electrics

- AC Contactor brand: Schneider

Parts & Valves

- Water softener brand: Pentair

- Heat exchanger brand (at 2nd stage): Danfoss

- Normally open/closed solenoid valve: SMC

In-House Designed and Manufactured Airend

Since 1988, Gairs has produced all single-screw airends in-house. Key features of the single-screw airend include optimized airflow for reduced energy consumption and a reliable compressed air supply. Its advanced rotor and star-wheel design minimizes radial and axial forces, resulting in low noise and minimal vibration. Additionally, it offers straightforward maintenance for those skilled in single-screw technology, with maintenance kits readily available.

Low Maintenance Cost

For routine maintenance, our PET bottling compressors require only the replacement of the air filter element, water filter element, and water softener element, minimizing parts replacement compared to reciprocating compressors. For annual maintenance cost details, please contact us.

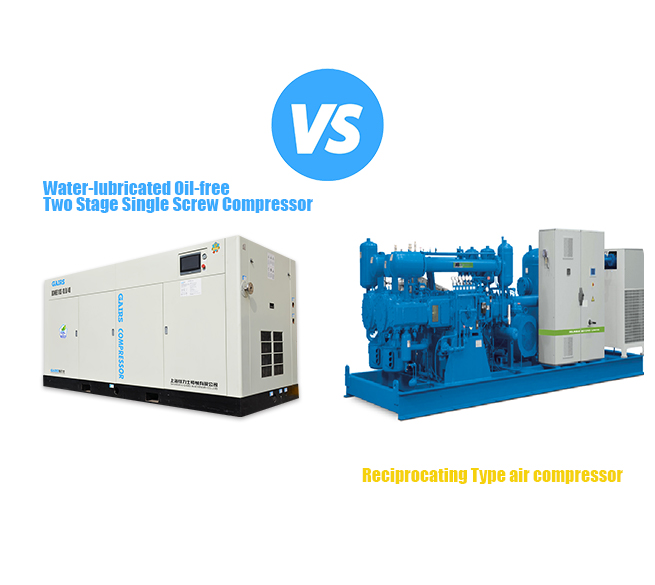

Comparison

| Water-lubricated Oil-free Single Screw Compressor |

Piston Compressor | |

| Efficiency | Auto air compensation due to VSD |

Provides less consistent air delivery due to air loss |

| Energy Conservation | 92kW motor power needed for producing 10m3/min at 30 bar | 110kW motor power needed for producing 10m3/min at 30 bar |

| Noise Level | ±70 dB(A) | ±100 dB(A) |

| Airend Structure | High efficiency, no clearance volume | Lower efficiency, 5% of air volume loss in 3-5 months |

| Vibration Level | ±3 mm/s | ±100 mm/s |

| Regular Maintenance | Air filter, water filter, and water softener resin elements only | Air filters, valves, piston rings, seals and gaskets, etc. |

| Regular Maintenance Time | 30 mins/time | 3-5 days/time |

Frequently Asked Questions

The following are frequently asked by our customers about OGW series water lubricated oil-free air compressors.

Gairs PET bottle blowing compressors are two-stage, water-injected single-screw compressors with dual motor and airend sets. Water is used as a cooling, sealing, and lubricating medium, which reduces the operating temperature to below 65°C and enhances efficiency and longevity, making it highly suitable for high-demand applications like PET bottle production.

Gairs began development of high-pressure two-stage compressors in 2008, with extensive testing and improvements before launching them commercially in 2016.

With over 30 years of R&D in single-screw technology and water lubrication (since 1988 and 1998, respectively), Gairs specializes deeply in this technology, providing high expertise and reliability rather than a broad but diluted product line.

For PET bottle compressors, the first-stage airend requires maintenance every 3 years (or 18,000 running hours), while the second-stage airend should be serviced every 2 years (or 12,000 running hours).

Typically, the lead time for a single-stage model is approximately 25-30 working days, while the lead time for a two-stage model is around 40-45 working days.