Refrigerated Air Dryer SAD Series

- Air Capacity: 1.2-300 [Nm³/min], 42-10500 [cfm]

- Pressure Dew Point: 2-10 [℃], 35.6-50 [℉]

- Pressure Range: ≤1.3 MPa

- Applicable Compressor Models: OGWY(B), OGWYC, OGWBD

- Product Introduction

- Features

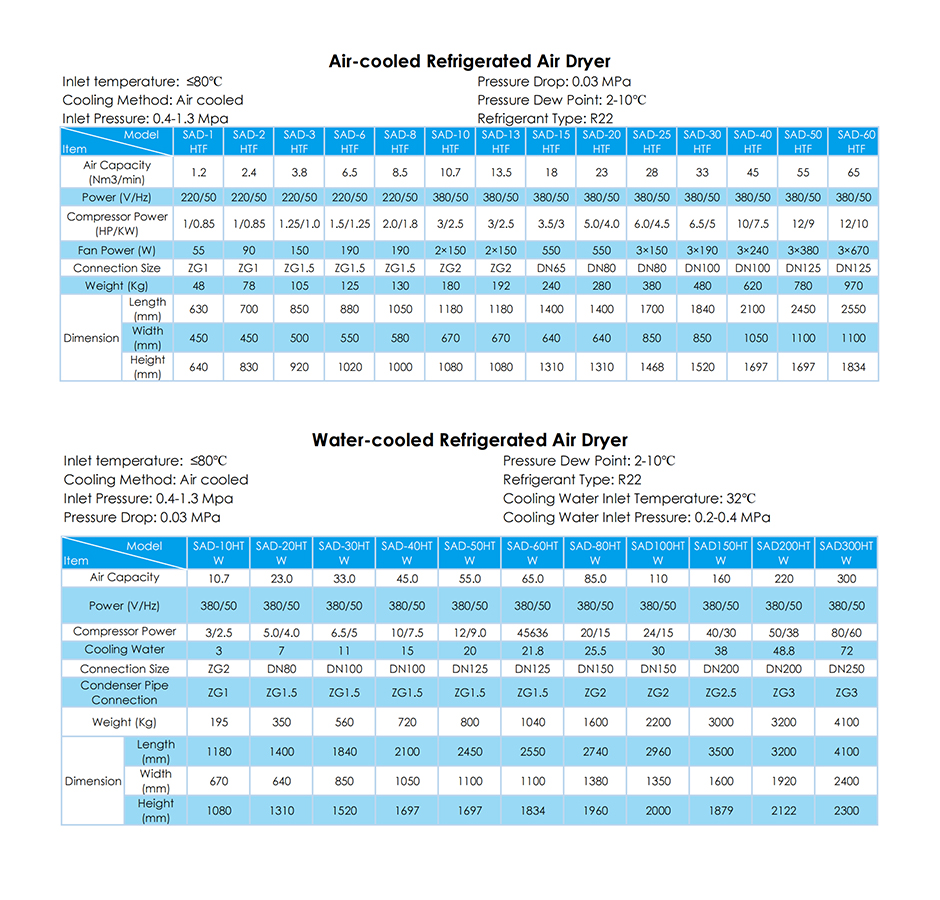

- Technical Specifications

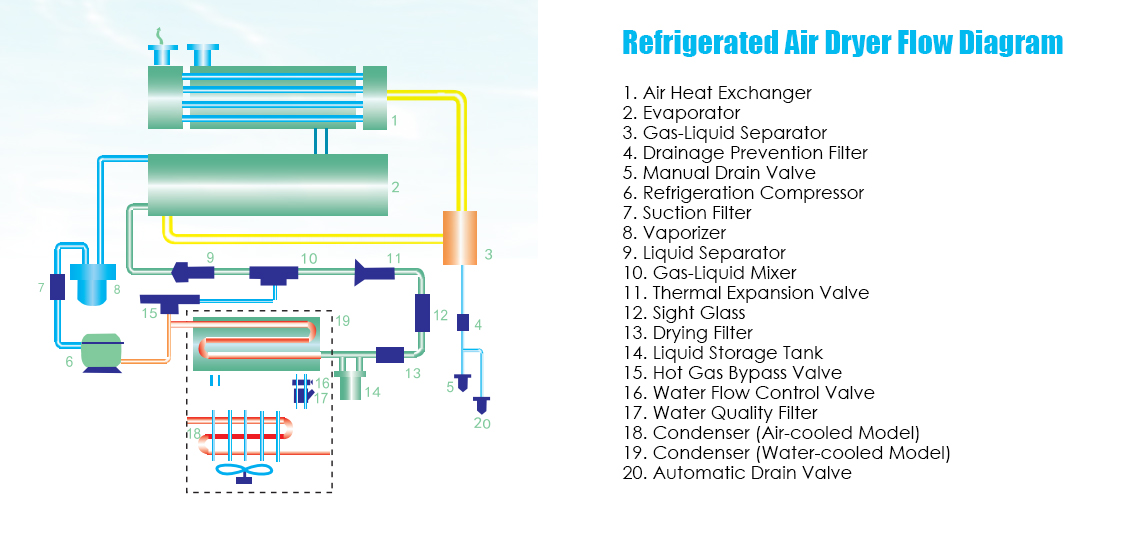

- Schematic Diagram

- Downloads

The operating principle of a compressed air dryer consists of three main components: the heat exchange system, refrigeration system, and electrical control system.

Compressed air first enters the precooler for air-to-air or air-to-water heat exchange, removing a portion of its thermal energy. It then passes through the heat exchanger, where it exchanges heat with the cold air that has been cooled to the pressure dew point after leaving the evaporator. This further reduces the temperature of the compressed air.

Subsequently, the compressed air enters the evaporator, where it undergoes heat exchange with the refrigerant, lowering its temperature to 0-8°C. At this temperature, moisture in the air condenses and is separated by the water-air separator before being discharged by the automatic drain valve. The cooled, dry air then returns to the heat exchanger, where it is reheated before being discharged.

Stable Performance

- Consistent exhaust pressure dew point

- Prevents ice blockage

- No moisture ingress into compressed air lines

Reliable Operation

- Carbon steel enclosure

- Utilizes high-quality components

- Features a simple and dependable design

- Efficient refrigeration control system (with hot gas bypass valve)

Easy Installation

- Ready for operation upon direct installation

- Single electrical interface

- All components are pre-adjusted for automatic regulation

Minimal Maintenance

- Reduced maintenance time with extended intervals

- Virtually no need for component replacements

Energy Efficient

- Enhances the lifespan and reliability of pneumatic tools and equipment

- Reduces pipeline leaks and lowers energy consumption

- Decreases the frequency of repairs for pneumatic tools, equipment, and lines

- Minimizes downtime for maintenance

- Significantly lowers the risk of product quality being affected by moisture

Frequently Asked Questions

The following are frequently asked by our customers about air compressor air dryer.

A refrigerated air dryer removes moisture from compressed air by cooling the air to low temperatures, causing water vapor to condense. The condensate is then removed, delivering dry air ideal for industrial use.

Moisture can cause corrosion in pipes, damage air compressors, and compromise product quality. A refrigerated air dryer prevents these issues, ensuring clean, dry air for efficient and safe operations.

There’s basically no maintenance needed for our refrigerated air dryer because no consumable parts are inside.

Yes, our refrigerated air dryers are designed to handle fluctuating air flow rates, making them suitable for industries with varying compressed air demands while maintaining optimal performance.

Refrigerated air dryers are generally energy-efficient, especially when equipped with energy-saving features like thermal mass technology, which reduces power usage during low air flow periods, lowering operational costs.