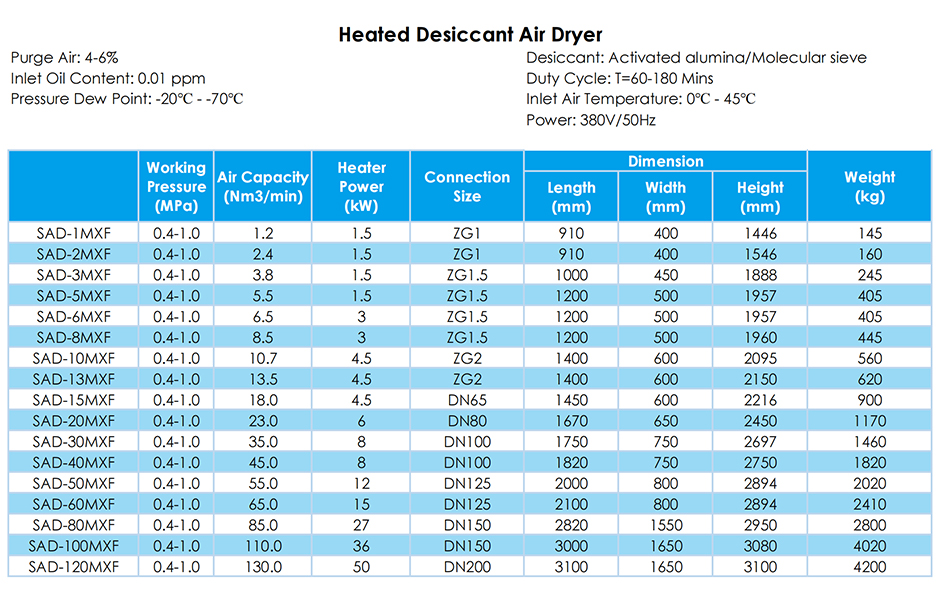

Externally Heated Desiccant Air Dryer SAD-MXF Series

- Air Capacity: 1.2-130 [Nm³/min], 42-4590 [cfm]

- Pressure Dew Point: -20–70 [℃], -4–94 [℉]

- Pressure Range: 0.4-1.0 MPa

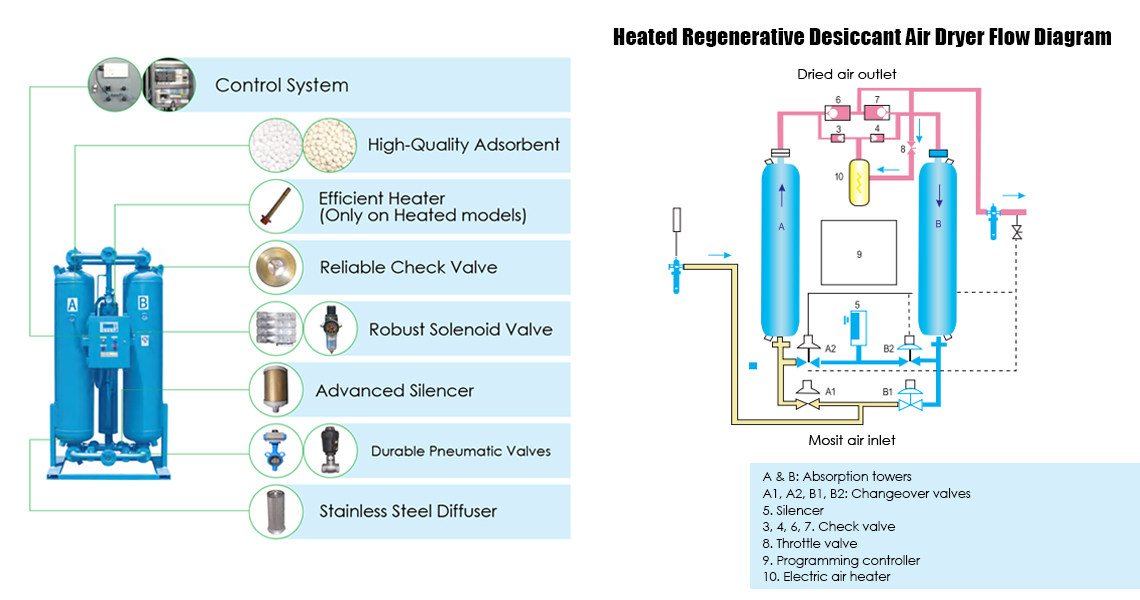

A heated regeneration desiccant air dryer removes moisture from compressed air using a desiccant. One tower adsorbs moisture while the other regenerates, releasing moisture through heat and reduced pressure. These dryers heat the expanded purge air using an electric air heater. The towers alternate in continuous cycles, ensuring a constant supply of dry air while minimizing energy consumption.

- Features

- Technical Specifications

- Schematic Diagram

- Downloads

Basics

- Pressure Dew Point as Low as -70°C

- Regeneration Air Consumption <7%

Control System

- Automated Control : Employs a microcontroller for stable and reliable operation, with optional PLC control for selection.

- User-Friendly Interface: Includes automatic valve status display and straightforward operation for easy maintenance.

- Alarm System: Equipped with alerts for high intake temperature, low intake pressure, and excessive heating temperature (for heated models).

- Energy Efficiency: Regenerated air consumption can be adjusted based on actual load and temperature, enhancing energy efficiency.

- Flexible Cycle Timing: Offers customizable switching cycle times to meet specific dew point requirements for products.

Spare Parts & Accessaries

- High-Quality Adsorbent: Utilizes premium high adsorption activated alumina for effective moisture removal.

- Efficient Heater: Features a high-performance heater for effective moisture removal and regeneration.

- Reliable Check Valve: Ensures dependable performance for system integrity.

- Robust Solenoid Valve: Modular design with operational indicators for easy maintenance; includes a dust filter to prevent contamination of pneumatic components, reducing valve failure rates.

- High-Quality Changeover Valves: Stable and reliable, ensuring the integrity of the operating process and extending the service life of components.

- Advanced Silencer: Made with high-temperature acoustic glass wool and specially treated sound-absorbing materials, achieving noise levels ≤ 72dB(A) during regeneration.

- Durable Pneumatic Valves: Offers longer lifespan compared to electric solenoid valves, ensuring stable long-term operation of the dryer.

- Stainless Steel Diffuser: Provides stability, diffusion, and filtration for airflow management.

Frequently Asked Questions

The following are frequently asked by our customers about compressor dryer.

Heated desiccant air dryers support air capacities ranging from 1.2 to 130 Nm³/min (42 to 4590 cfm), accommodating various application sizes from smaller systems to large-scale industrial processes.

These desiccant dryers can deliver an impressive dew point range of -20 to -70°C (-4 to -94°F), ensuring ultra-dry air for applications that demand minimal moisture content to prevent corrosion and contamination.

Our heated desiccant air dryers are designed to work within a pressure range of 0.4 to 1.0 MPa, making them compatible with diverse industrial applications that require flexible pressure handling.

Heated desiccant dryers use an external heat source to regenerate the desiccant, reducing the amount of compressed air needed for regeneration. This results in lower operating costs and increased efficiency compared to heatless dryers.

Desiccant replacement is generally recommended every 2 years, depending on usage and air quality. Routine maintenance, including desiccant checks and heater inspections, is recommended every 6-12 months. Regular maintenance can prolong the desiccant’s life and ensure that the dryer operates at peak efficiency.