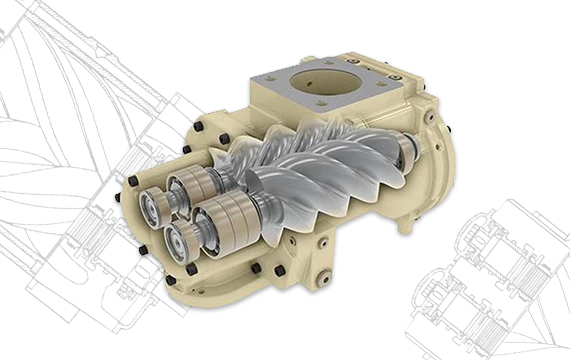

What is an Oil Lubricated Rotary Screw Compressor?

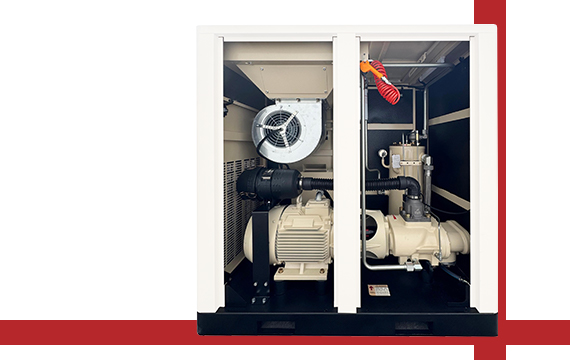

An oil-lubricated rotary screw compressor uses oil to seal, cool, and lubricate its internal components during compression. This design ensures efficient, continuous operation, making it ideal for industrial applications requiring high-duty performance.

A rotary screw air compressor uses twin spiral screws to compress air through positive displacement. In oil-lubricated systems, oil fills the space between the helical rotors, creating an air-tight hydraulic seal and efficiently transferring mechanical energy. As atmospheric air enters the system, the interlocking screws push it through the compression chamber. The oil also cools, seals, and lubricates the internal components, reducing friction and minimizing air leakage. This design allows for continuous, high-performance operation with steady air flow, making it ideal for demanding industrial applications. With lower maintenance requirements and an extended lifespan, these compressors deliver reliable and energy-efficient performance.

Oil-Injected Rotary Screw Compressors

Power: 7.5-250 kW

Pressure: 0.8 MPa

FAD Capacity: 1.1-45.5 m3/min

Number of compression stage: 1

Power: 15-315 kW

Pressure: 0.8 MPa

FAD Capacity: 2.8-66.0 m3/min

Number of compression stage: 2

Power: 7.5-250 kW

Pressure: 0.8 MPa

FAD Capacity: 1.1-45.5 m3/min

Number of compression stage: 1

Power: 7.5-22 kW

Pressure: 0.8-1.6 MPa

FAD Capacity: 1.1-2.3 m3/min

Number of compression stage: 1

Power: 37-405 kW

Pressure: 3.0-4.0 MPa

FAD Capacity: 3.5-45.0 m3/min

Number of compression stage: 2-3

Industries That Use Rotary Screw Air Compressors

Features That Shape KLINA Ratory Compressors

Designed for optimal energy savings, Klina rotary screw compressors reduce energy and operating costs. With airends featuring 8-9 bearings in single-stage models and 20 bearings in two-stage models, they deliver exceptional efficiency.

Built with high-quality components, Klina rotary screw compressors ensure consistent performance and minimize downtime. Their robust design reduces maintenance costs, ensuring long-term reliability.

Klina rotary screw compressors are compact, making them ideal for industries with limited space. Their design allows for easy installation in various industrial environments.

Available in various capacities, Klina screw compressors cater to a wide range of industries, from manufacturing to construction and automotive, offering flexible solutions for different applications.

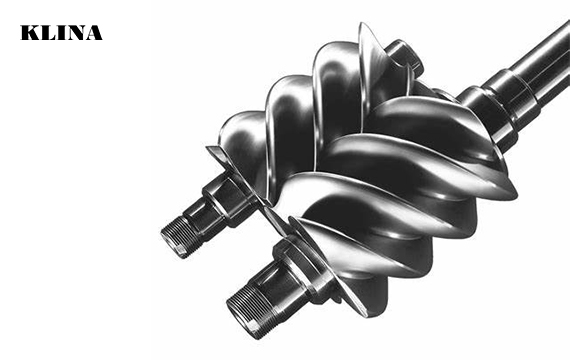

Industry-Leading Airend

KLINA airends are equipped with 8-9 bearings in single-stage models and 20 bearings in two-stage models, delivering outstanding efficiency and durability. This advanced design ensures superior performance, even in demanding applications, while maximizing energy savings and operational reliability.

Efficiency with Variable Speed

More efficient than piston compressors, rotary screw compressors offer superior performance while significantly reducing energy consumption. With Klina VSD compressors, they can adapt to real-time demand, thus lowering operational costs by up to 30%.

Robust Design

Rotary screw air compressors are built for durability, featuring lower maintenance requirements. They are designed to operate in both high and low-temperature environments, ensuring reliable performance in a wide range of conditions.

How Do Rotary Screw Air Compressors Work?

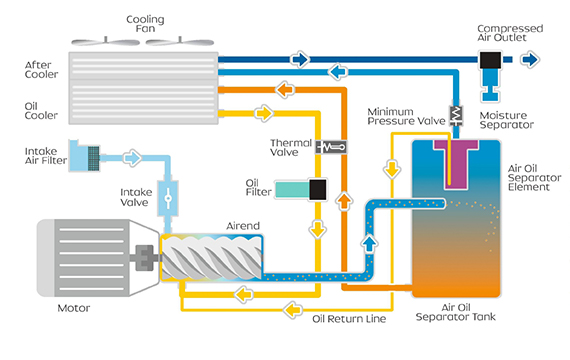

KLINA Oil-flooded rotary screw compressors operate by using two interlocking helical rotors that spin in opposite directions to compress air. As air enters the system, it fills the gap between the screw threads or grooves, where it is compressed as the screws rotate. The majority of rotary screw compressors are oil-flooded, where oil is used to seal, lubricate, and cool the compression process. However, oil-free screw compressors are also available for applications requiring contamination-free air.

- Air intake: Atmospheric air is drawn into the compressor through an intake valve.

- Rotor compression: Two interlocking helical rotors compress the air as they rotate.

- Oil injection: Oil is injected into the compression chamber, forming a seal and enhancing compression efficiency.

- Cooling: The oil absorbs heat generated during compression, cooling both the air and compressor components.

- Air-oil separation: After compression, the air-oil mixture is directed to an oil separator, where the oil is removed from the compressed air.

- Oil recirculation: The separated oil is recycled back into the system for reuse.

- Compressed air delivery: The purified, compressed air is then delivered to the air system for use.

Why KLINA Air Compressors?

KLINA, a complementary brand to GAIRS, provides both oil-injected rotary screw compressors and oil-free single screw compressors. These models offer economical and practical solutions for clients looking to meet their compressed air demands efficiently.

Both GAIRS and KLINA belong to the GAIRS Group. GAIRS targets the high-end compressed air market and has shifted its focus solely to water-injected oil-free single screw technology. GAIRS’ mission is to deliver 100% clean compressed air while ensuring every GAIRS compressor has the lowest Global Warming Potential (GWP), contributing to a more sustainable environment.

KLINA, in collaboration with trusted partners, offers both oil-injected rotary screw compressors and water-injected oil-free single screw compressors. These models provide efficient, economical, and practical solutions for clients’ compressed air needs.

Yes, we accept OEM orders. We are happy to customize our products to meet your specific requirements. Please provide detailed specifications, including design, configuration, and any other special requests, so we can offer the best solution tailored to your business.

Yes, though compressors with different pressure are not shown on the page, you can always give us an email for inquiry.

Related Product

You May Also Want To Know

The following are frequently asked by our customers about KLINA rotary screw type air compressors.

When compressor encounters a problem, please contact our sales representitives for remote video guide first. Do not change the operation parameter at will.

Rotary screw compressors provide a continuous airflow and are more energy-efficient, with fewer maintenance needs compared to piston compressors, which work in cycles.

VSD technology adjusts the compressor’s motor speed based on real-time air demand, reducing energy consumption and operational costs by up to 30%.

Rotary screw compressors require less maintenance than piston compressors due to fewer moving parts, which reduces wear and tear, but regular servicing for filters, oil, and other consumable parts is necessary.

Typically, the lead time for a rotary compressor is approximately 25-30 working days.