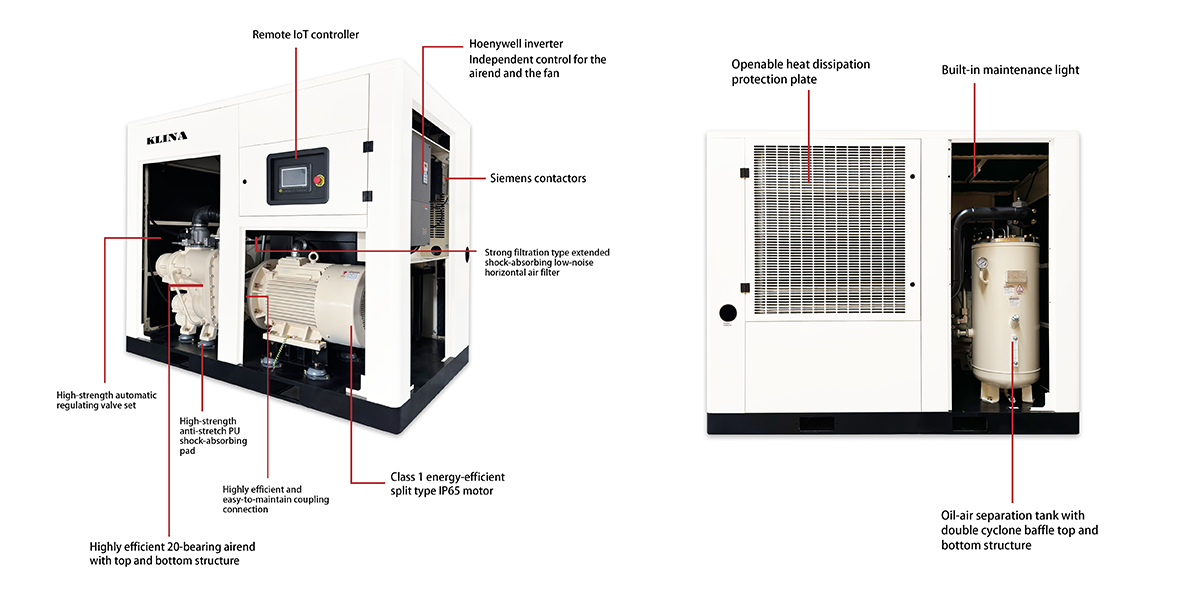

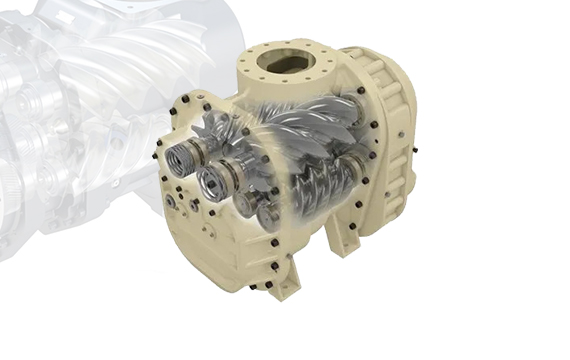

The KLINA JLYC Series variable speed rotary screw air compressor provides reliable performance as it uses a 2-stage airend featuring 20 bearings, delivering high airflow, low noise, and extended durability without rapid performance decline.

Two Stage Variable Speed Oil Injected Rotary Screw Compressor Model: JLYC

- Discharge Pressure: 8 [bar], 116 [psig]

- Free Air Delivery: 2.8-66.0[m³/min], 99-2330 [cfm]

- Rated Motor Power: 15-315 [kW], 20-422 [hp]

A variable speed air compressor features a specialized drive that regulates and adjusts operating speed. This design provides numerous advantages, including maintaining consistent pressure, preventing power surges, and reducing energy consumption. Over time, many users find significant savings on energy costs with variable speed air compressors.

- Deatails

- Technical Specifications

- Configuration

- Downloads

| Model | FAD Capacity | Discharge Pressure | Motor Rating | Sound Level | Voltage/Frequency | Starting Method | Discharge Connection | Dimensions | Weight |

| m³/min | MPa | kW | dB(A) | V/Hz | inch | L x W x H (mm) | kg | ||

| JLYC15F | 2.8 | 0.8 | 15 | 67±2 | 380V/50Hz | Inverter Start | G1 1/4 | 1580*1080*1290 | 580 |

| JLYC18F | 3.5 | 0.8 | 18.5 | 67±2 | G1 1/4 | 1580*1080*1290 | 600 | ||

| JLYC22F | 4.2 | 0.8 | 22 | 67±2 | G1 | 1580*1080*1290 | 600 | ||

| JLYC30F | 6.5 | 0.8 | 30 | 68±2 | G1 1/2 | 1800*1180*1520 | 820 | ||

| JLYC37F | 7.2 | 0.8 | 37 | 68±2 | G1 1/2 | 1800*1200*1540 | 860 | ||

| JLYC45F | 9.8 | 0.8 | 45 | 69±2 | G2 | 1800*1200*1540 | 1700 | ||

| JLYC55F | 12.6 | 0.8 | 55 | 71±2 | G2 | 2100*1350*1750 | 1800 | ||

| JLYC75F | 16.5 | 0.8 | 75 | 72±2 | G2 | 2100*1350*1750 | 1950 | ||

| JLYC90F | 20.0 | 0.8 | 90 | 73±2 | G2 1/2 | 2300*1470*1940 | 2300 | ||

| JLYC110F | 23.6 | 0.8 | 110 | 74±2 | G2 1/2 | 2450*1550*2010 | 2400 | ||

| JLYC132F | 28.2 | 0.8 | 132 | 76±2 | G2 1/2 | 2450*1550*2010 | 2450 | ||

| JLYC160F/S | 34.2 | 0.8 | 160 | 78±2 | DN100 | 2450*1550*2010 | 3800 | ||

| JLYC185F/S | 38.6 | 0.8 | 185 | 80±2 | DN100 | 3388*2130*2000 | 4100 | ||

| JLYC200F/S | 43.3 | 0.8 | 200 | 82±2 | DN100 | 3388*2130*2000 | 4800 | ||

| JLYC220F/S | 48.0 | 0.8 | 220 | 82±2 | DN100 | 4120*2130*2000 | 5100 | ||

| JLYC250F/S | 52.5 | 0.8 | 250 | 83±2 | DN100 | 4120*2130*2000 | 5600 | ||

| JLYC280F/S | 54.0 | 0.8 | 280 | 85±2 | DN100 | 4350*2050*2000 | 6000 | ||

| JLYC315F/S | 66.0 | 0.8 | 315 | 88±2 | DN100 | 4350*2050*2000 | 6800 |

* JLYC160F=Air cooled unit, JLYC160S=Water cooled unit

*Design and specifications are subject to change without prior notice or obligation.

JLYC Model Configuration

Klina Airend

- Two-stage airend featuring 20 bearings

Permanent Magnet Motor

- Motor Enclosure Protection: IP65

- Split type

- Coupling connection

Inverter & PLC controller

- Brand: Honeywell

- Full color touch-screen remote loT controller

- Independent control for both the airend and the fan

Centrifugal Fan (air-cooled unit)

- Enhanced cooling efficiency

- Reduced noise levels

Electrics

- AC Contactor brand: Schneider

Air Filter

- Strong filtration type extended shock-absorbing air filter

Industry-Leading Airend

KLINA airends are equipped with 20 bearings in two-stage models, delivering outstanding efficiency and durability. This advanced design ensures superior performance, even in demanding applications, while maximizing energy savings and operational reliability.

High Efficiency

Our reliable dual-stage air compressor provides up to 20% energy savings compared to single-stage compressors, ensuring enhanced efficiency and reduced operational costs in demanding applications.

Easy Maintenance

KLINA rotary screw compressors are designed for easy maintenance, featuring a built-in maintenance light, removable access ports for the inverter and cooling fan, an openable top cover, and a dust removal air gun.

Frequently Asked Questions

The following are frequently asked by our customers about KLINA rotary screw type air compressors.

How does a rotary screw compressor differ from a piston compressor?

Rotary screw compressors provide a continuous airflow and are more energy-efficient, with fewer maintenance needs compared to piston compressors, which work in cycles.

What are the benefits of VSD (Variable Speed Drive) in rotary screw compressors?

VSD technology adjusts the compressor’s motor speed based on real-time air demand, reducing energy consumption and operational costs by up to 30%.

How much maintenance does a rotary screw air compressor require?

Rotary screw compressors require less maintenance than piston compressors due to fewer moving parts, which reduces wear and tear, but regular servicing for filters, oil, and other consumable parts is necessary.

How long is the airend lifespan?

The KLINA airend is desgined for 100,000 hours.

What's the lead time?

Typically, the lead time for a rotary compressor is approximately 25-30 working days.

Send Your Inquiry Today