High Pressure Reciprocating Air Compressor JLHP Series

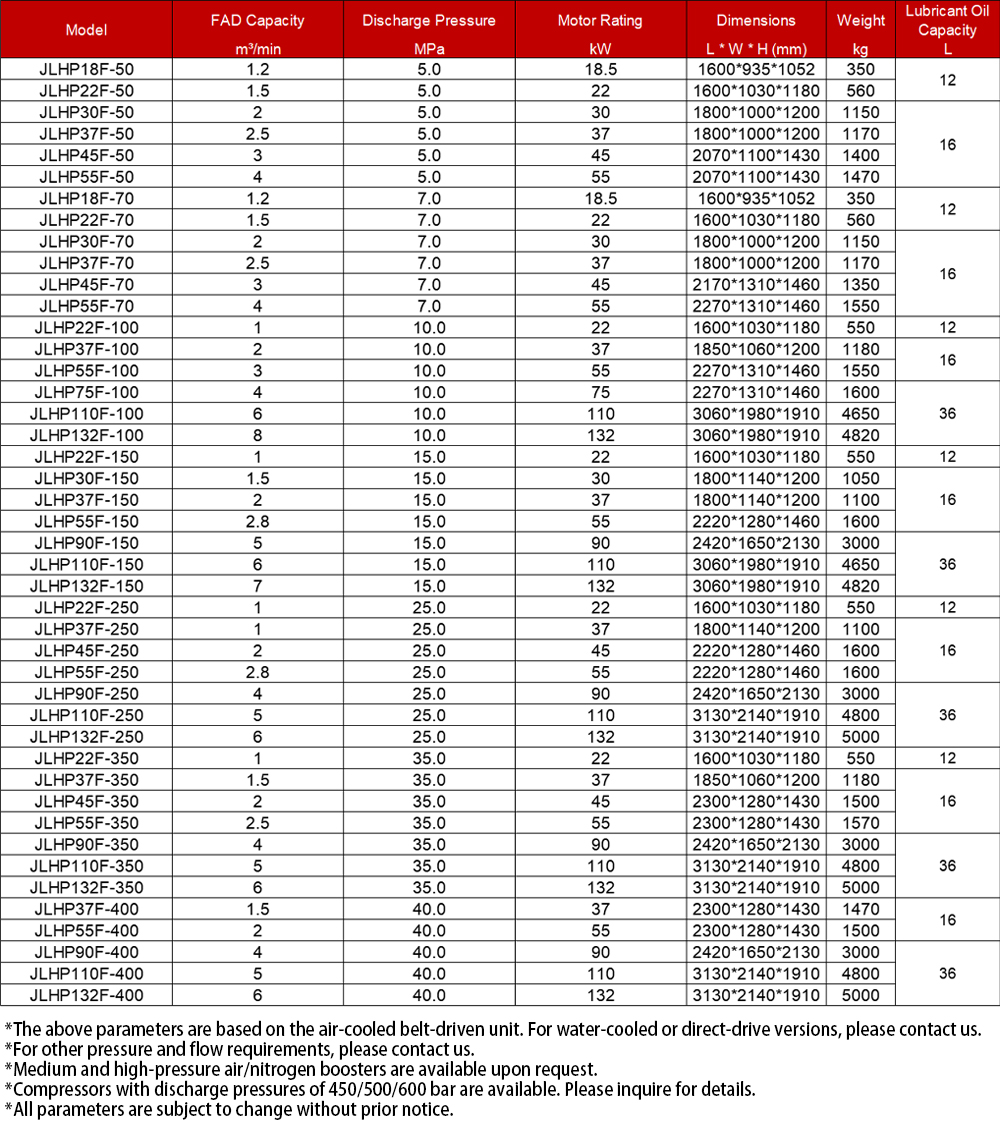

- Discharge Pressure: 30-600 [bar], 435-8702 [psig]

- Free Air Delivery: 0.1-6.0 [m³/min], 3.5-211.9 [cfm]

- Rated Motor Power: 3-132 [kW], 4-177 [hp]

The JLHP series high pressure reciprocating air compressor is designed for demanding applications, featuring an air-cooled airend, exceptional oil lubrication, and a robust cooling system. Engineered for heavy-duty and continuous operations, it ensures reliable performance in complex environments, making it ideal for high-pressure, heavy-duty tasks.

- Features

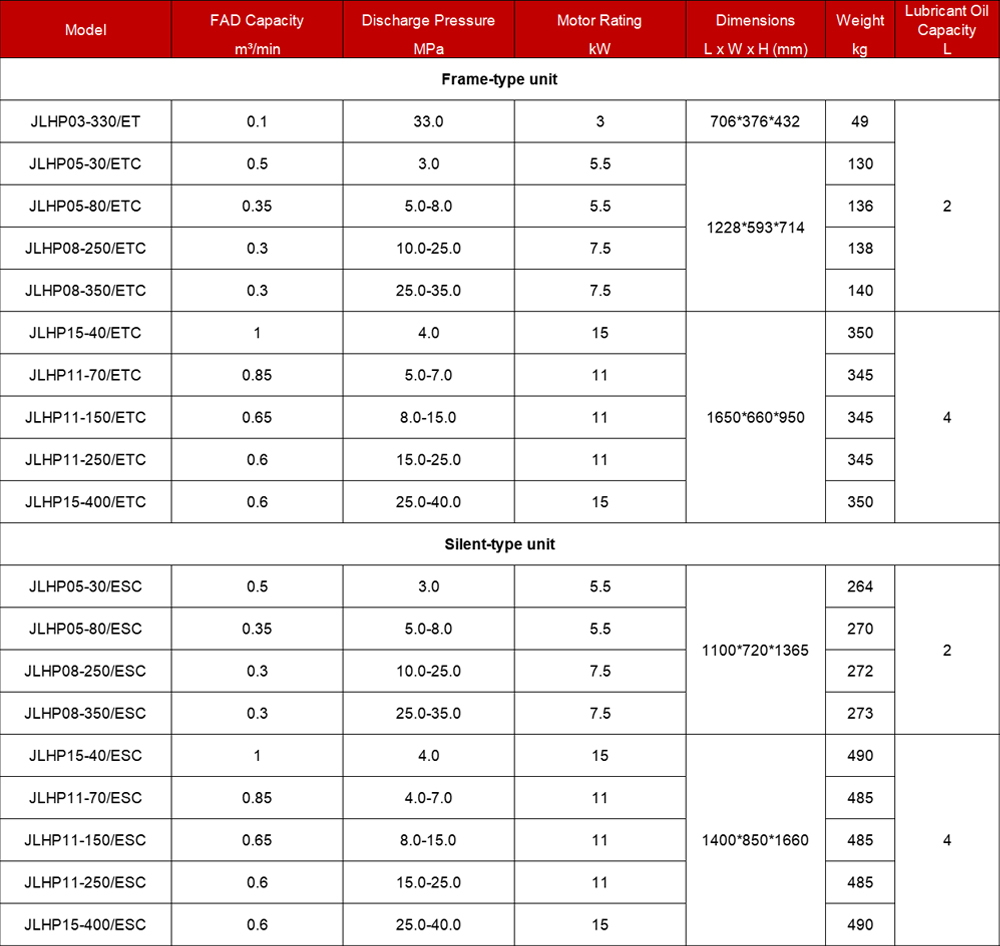

- Technical Specifications

- Downloads

Key Features of High Pressure Reciprocating Air Compressor

Airend

- Air-Cooled Airend: Tailored for demanding and complex application environments. Multi-stage compression reduces load per stage, while deep-finned cylinders enhance operational reliability.

- Precision Valve Selection: Intake, exhaust, and safety valves are carefully chosen to adapt to various operating conditions.

- Heavy-Duty Filtration: Intake filter with silencer cleans incoming air or other gases, which is designed to perform under special operational conditions.

Lubrication System

- Oil Pump-Driven Lubrication: Delivers precise lubrication to all moving components for reliable operation.

- Lubrication Monitoring System: Ensures stable and secure performance.

- Oil Filtration System: Precisely filters lubricant, safeguarding system integrity.

Cooling System

- Enhanced Heat Dissipation: Deep-finned cylinders and cylinder heads with oversized coolers effectively reduce operating temperatures at all stages.

- Crankshaft-Driven Cooling Fan: Provides forced cooling to the airend and air-cooled cooler.

- High-Efficiency Interstage Cooling: Reduces discharge temperatures for each stage.

- Customizable Cooling Options: Air-cooled or water-cooled coolers available to match specific operating conditions.

- Post-Cooling Features: Each stage’s cooler includes separators and an automatic drainage system.

System Features

Standard & Custom Control Systems:

- KLINA offers a standard control system with options for tailored solutions to meet customer-specific requirements.

- Designed for efficient and stable operation, whether in continuous or intermittent modes.

Modular Design:

- Provides optimized technical and economic solutions.

- Enhances flexibility and efficiency through universal modular combinations of pistons, cylinders, cylinder heads, and valves.

Material & Component Quality: Ensures high efficiency and reliability for each compressor.

Versatile Configurations: Available in various models to suit different usage scenarios.

Heavy-Duty Applications: Built for continuous operation in demanding environments.

Cooling Options: Air-cooled and water-cooled systems for diverse requirements.

Comprehensive Solutions: From compressors to entire compression systems, KLINA offers one-stop services.

Design Features

- Simplified installation and maintenance.

- Excellent balance and low vibration.

- Reduced maintenance workload and operating costs.

- Low compression ratio and minimal temperature rise.

- No need for special foundation requirements.

- High operational efficiency.

- Designed for continuous heavy-duty operation.

- Low operating speed for extended service life.

- Maximum pressure up to 600 Bar.

- Quiet operation.

Frequently Asked Questions

The following are frequently asked by our customers about high pressure reciprocating compressor.

The modular design provides flexible technical and economic solutions, allowing customers to customize combinations of pistons, cylinders, cylinder heads, and valves for enhanced efficiency. It also simplifies installation and maintenance, reducing overall operational costs.

The JLHP series features an air-cooled airend with multi-stage compression, reducing load per stage. The deep-finned cylinders enhance operational reliability, making it ideal for complex, demanding applications.

The JLHP series offers both air-cooled and water-cooled options, allowing customization based on specific operating conditions. It features deep-finned cylinders, oversized coolers, and high-efficiency interstage cooling to manage temperatures effectively.

The JLHP series offers both oil injection and oil free options. For details, please contact our expert.

The JLHP series is designed for continuous heavy-duty applications in industries such as high-pressure testing, pipeline testing, and the marine industry. With its robust cooling, lubrication, and filtration systems, it ensures reliable operation even under the most demanding conditions.