Why Follow a Preventive Maintenance Schedule?

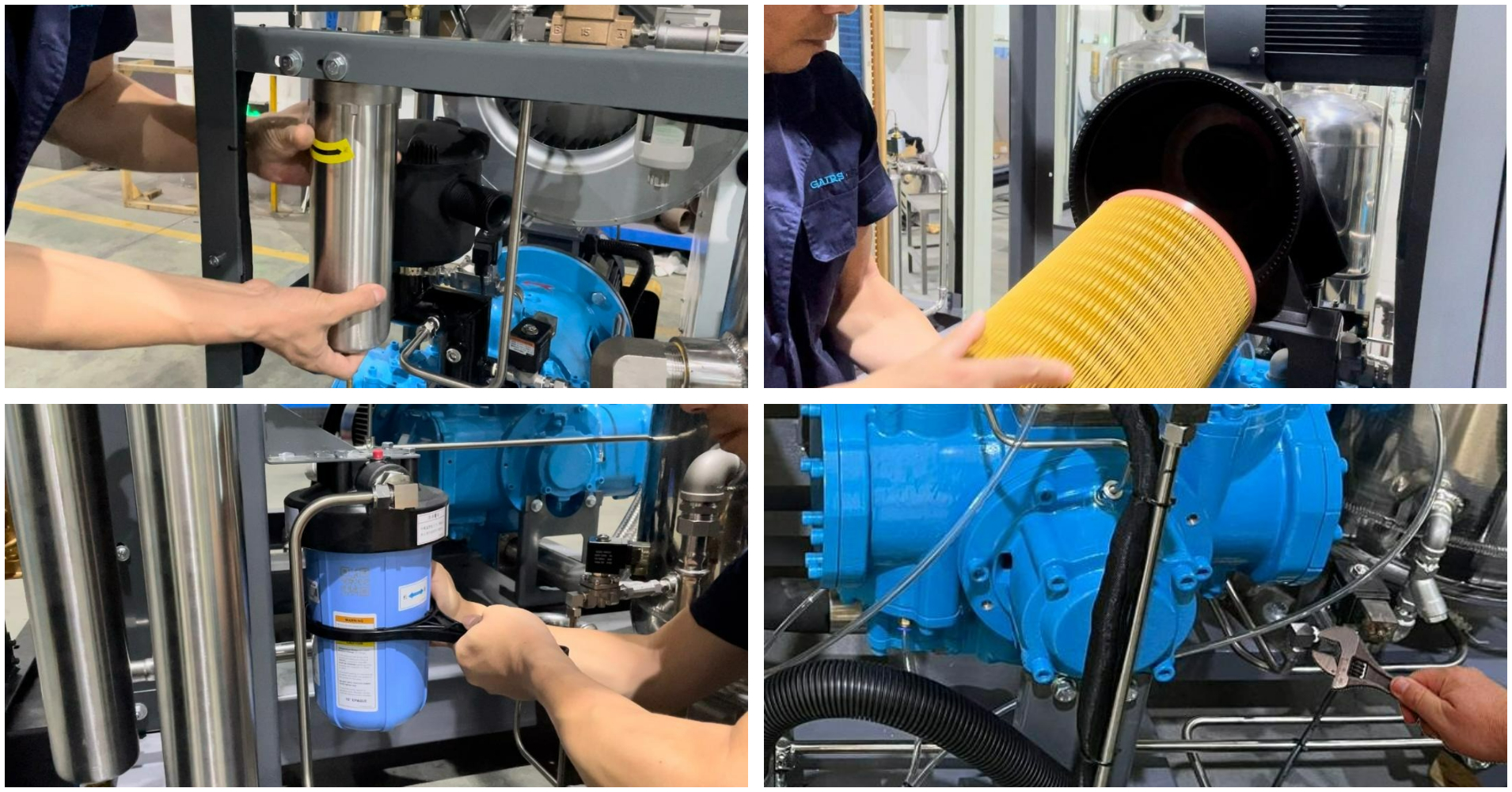

Following a preventive maintenance schedule for your air compressor is crucial for maximizing its efficiency, extending its lifespan, and avoiding costly breakdowns. By adhering to a regular maintenance plan, you can ensure that all critical components, such as the air end, filters, and lubrication system, are properly maintained. This not only helps in reducing the risk of unexpected failures but also improves overall system performance and energy efficiency. Additionally, regular servicing allows for the early detection of potential issues, which can be addressed before they lead to more serious damage. As a result, you reduce downtime, enhance the reliability of your equipment, and lower long-term operating costs. Below is the regular maintenance illustration which includes water filter element, air filter element, water softener filter replacement and daily valves check.

Gairs Air End Overhaul Schedule and Requirements:

To ensure optimal uptime and performance, it’s crucial to follow a maintenance schedule for your Gairs air end.

Single-Stage Compressor:

- Overhaul interval: Every 18,000 running hours or 3 years.

Two-Stage Compressor:

- 1st Stage Air End: Overhaul every 18,000 running hours or 3 years.

- 2nd Stage Air End: Overhaul every 12,000 running hours or 2 years.

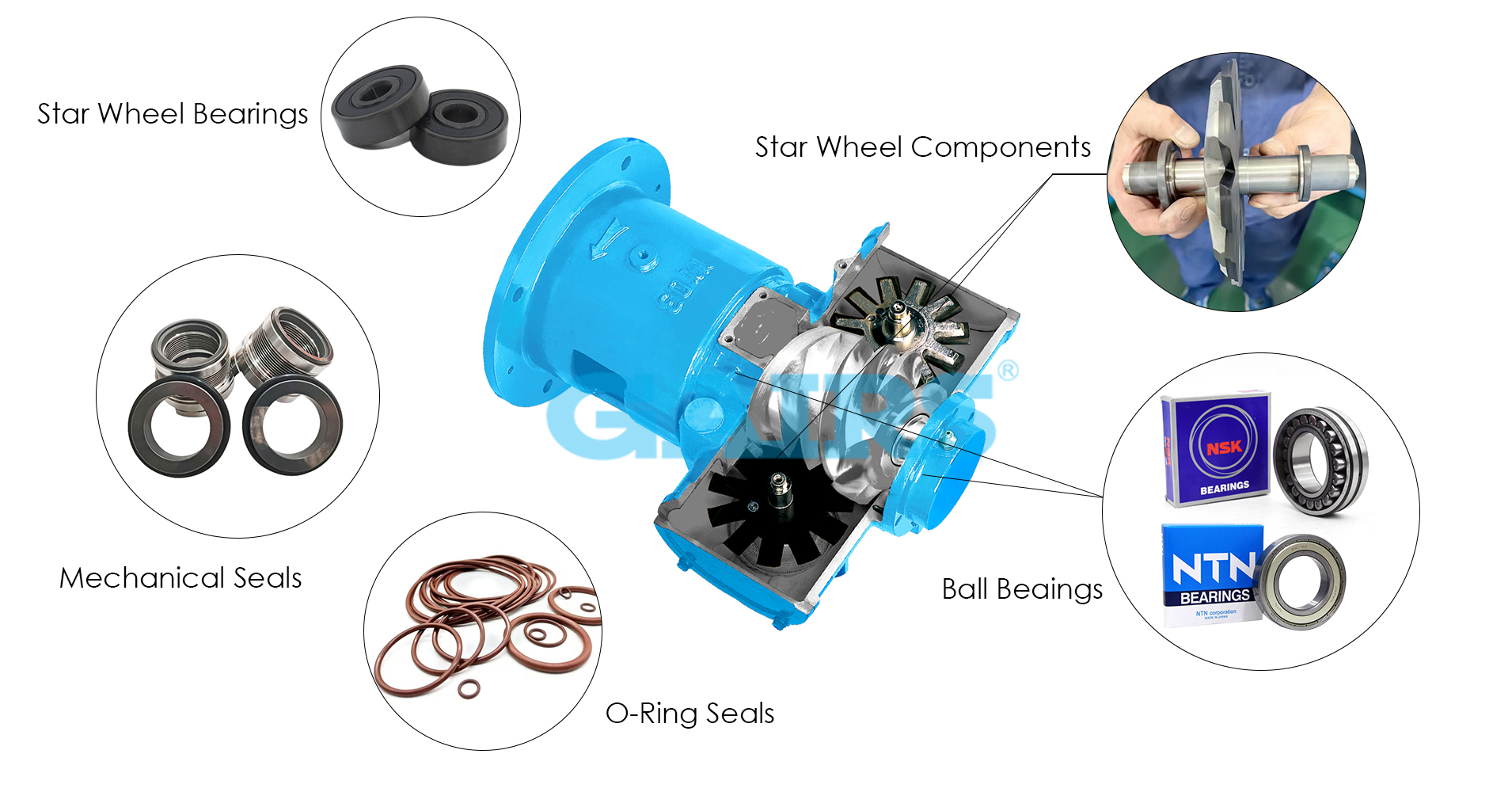

During the overhaul, certain parts inside the air end need to be replaced, including the star wheels, bearings, mechanical seals, O-ring seals, and star wheel bearings, etc. Please note that the screw rotor will not be replaced as part of the overhaul unless it’s damaged. This approach significantly reduces costs compared to replacing the entire air end, while maintaining the high efficiency and reliability of your compressor. Regular maintenance ensures that the air end continues to operate at peak performance, extending its service life and preventing unexpected failures.

Parts to be Replaced During Overhaul:

- Star wheels

- Bearings

- Mechanical seals

- O-ring seals

- Star wheel bearings

If you notice any problems with the air compressor, we recommend first referring to the user manual and following the troubleshooting procedures outlined. This will help you address common issues and ensure you are taking the correct steps to maintain your system.

If you are unable to resolve the issue through the user manual’s troubleshooting guide, please contact us. We offer assistance via email or video support, send a technician for on-site troubleshooting, or assess whether the product needs to be sent to a nearby service center for inspection and repair.