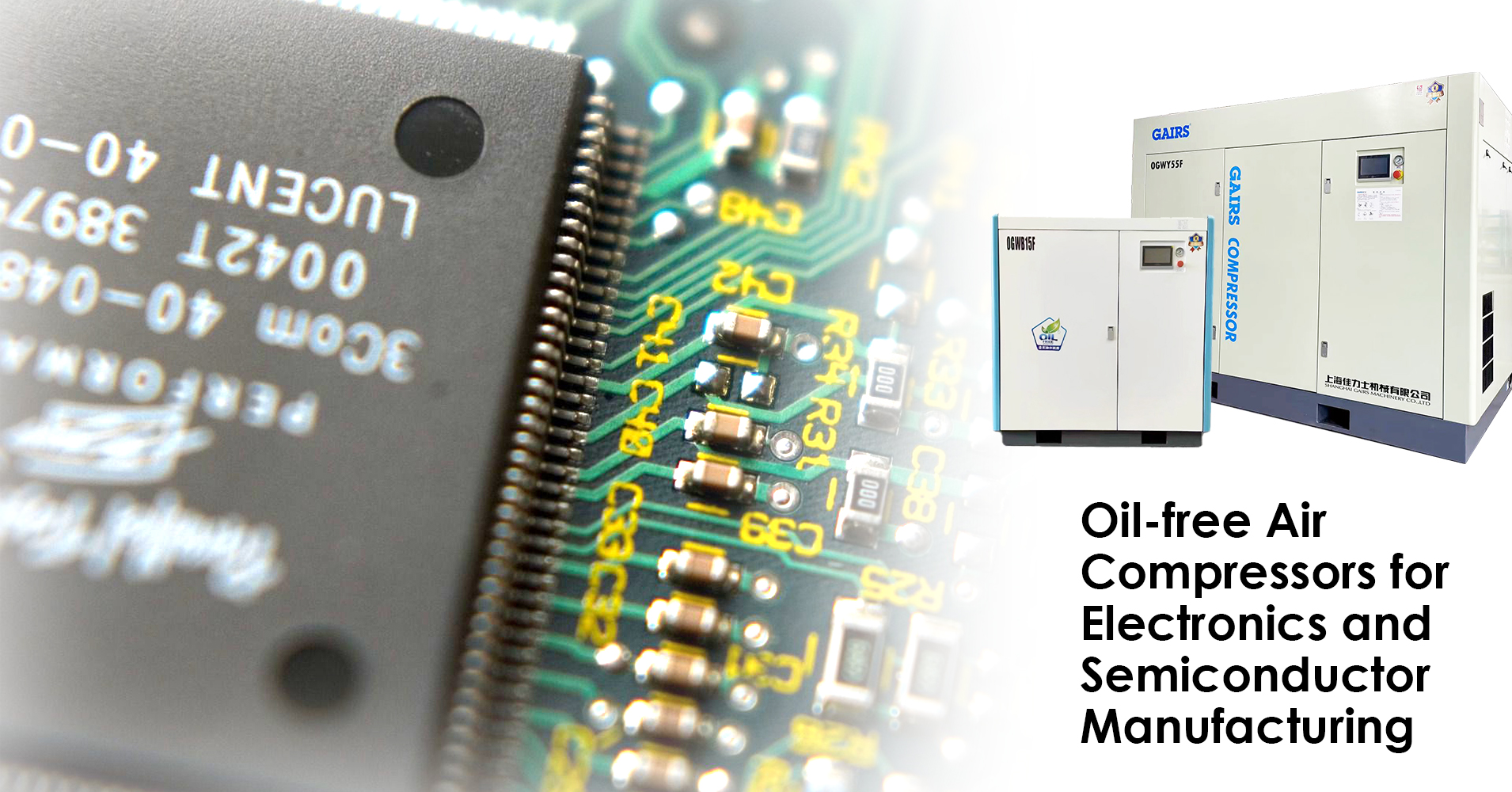

Compressed Air Solution for Electronics Industry

Why Does the Electronics Industry Need 100% Clean Compressed Air?

In the electronics industry, clean and reliable compressed air is essential for maintaining high standards of production, quality control, and equipment longevity. Contaminated air can lead to serious issues, including:

- Damage to Sensitive Equipment: Contaminated compressed air can cause corrosion and performance degradation in precision electronics and semicondutor manufacturing and assembly equipment.

- Product Quality Issues: Contaminants in compressed air can lead to defects in the final product, such as circuit board malfunctions, which are costly to repair.

- Operational Downtime: Contaminated or inadequate air supply can cause machinery breakdowns, leading to costly downtime and potential delays in production schedules.

- Increased Maintenance Costs: Air impurities can accelerate wear on equipment, leading to more frequent maintenance and part replacements.

The Importance of a Dedicated and Ventilated Compressor Room

For electronics manufacturers, the air quality in the compressor room is just as critical as the quality of the air produced. A key consideration in compressor setup is having a dedicated and well-ventilated compressor room. Without proper ventilation, harmful chemicals like sulfides (common in electronics production) can carry over into the air system. These gases can react with the compressor’s air end, leading to:

- Corrosion and Contamination: Chemical reactions between sulfide gases and metal components can lead to rust and contamination, reducing the lifespan and efficiency of the compressor.

- Increased Maintenance: The presence of corrosive chemicals requires more frequent maintenance, which results in increased operational costs and machine downtime.

Gairs’ Solution: Water-Injected Oil-Free Compressors

GAIRS offers water-injected oil-free compressors that provide clean, efficient, and reliable compressed air, making them the ideal solution for the sensitive needs of the electronics industry. Our OGW series compressors ensure 100% oil-free compressed air, reducing the risk of contamination and maximizing the lifespan of your equipment.

Models for the Electronics Industry:

Key Features:

- TÜV Certified Class 0: Certified for 100% oil-free air, preventing contamination that could damage sensitive electronics.

- ISO-8573 Compliance: Meets the highest standards for air quality, essential for electronics manufacturing.

- Energy Efficient: Water-injected technology reduces energy consumption, helping lower operating costs.

- Durability: Robust design capable of handling continuous operations, ensuring reliability in demanding environments.

- Low Maintenance: Fewer moving parts mean reduced maintenance requirements and greater uptime.

Applications of Compressed Air in Electronics Production

1. PCB Assembly and Soldering

Compressed air is used for cleaning and cooling printed circuit boards (PCBs) during the assembly and soldering process. Clean air ensures there is no contamination, which could compromise the performance of the final product.

2. Conveyor Systems

Air-driven conveyor systems are used to transport delicate electronic components without causing damage or contamination.

3. Cleaning and Drying

Compressed air helps to remove dust and residues from delicate electronics, ensuring that they are free of particles that could lead to malfunctions.

4. Equipment Cooling

Air compressors power cooling systems that regulate temperatures in electronic production equipment, preventing overheating and maintaining optimal performance.

5. Packaging

Clean, dry air is essential for packaging sensitive electronics to avoid contamination during packaging processes and to ensure the integrity of the product.

Why Choose GAIRS Water-Injected Compressors for Electronics Operations?

- Superior Air Quality: Guarantees 100% oil-free air, eliminating risks associated with air contamination in sensitive electronics manufacturing processes.

- Operational Efficiency: Our compressors are designed to optimize energy usage, saving you operational costs in the long run.

- Reliability: With fewer moving parts and advanced technology, our compressors deliver dependable, continuous performance.

- Environmentally Friendly: Water-injected technology minimizes environmental impact.