Water Lubricated Compressor Installation Guide

Proper compressor setup is crucial upon receipt to ensure smooth operation. Below are the key steps to properly set up your water-cooled 2-stage oil-free compressor:

Step 1: Inspect for External Damage

- Carefully inspect the compressor for any visible damage.

- Ensure all parts and components are in good condition.

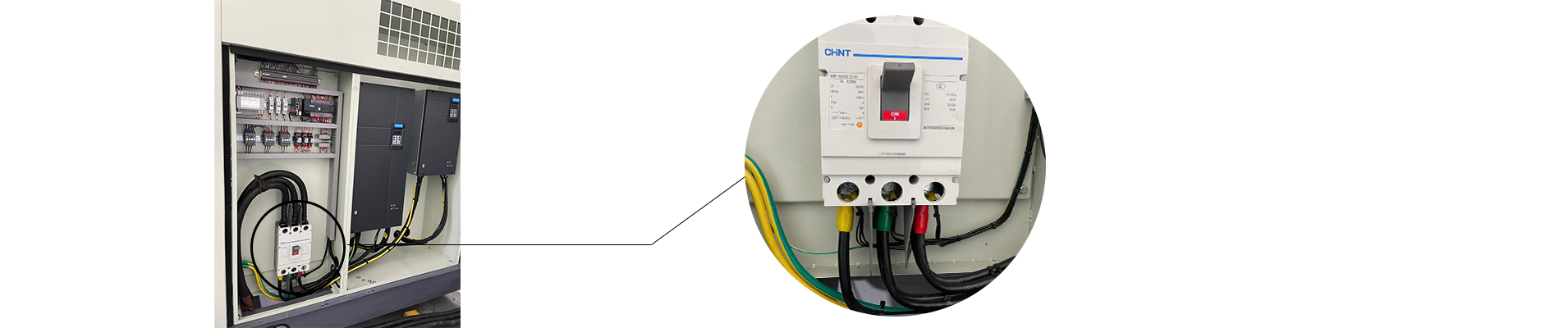

Step 2: Power Cable Connection

- Connect the power cables as per the specifications.

- Note: For three-phase electric connection, ensure phase sequence protection is properly set. If you hear an alarm before startup, swap any two of the incoming wires.

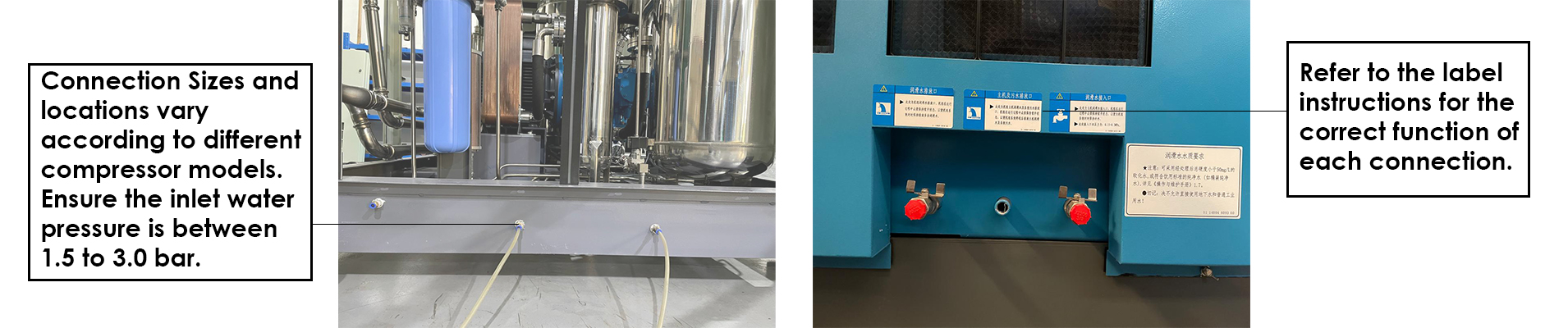

Step 3: Lubricating & Cooling Water Connection

- Connect the lubricating inlet and outlet to the specified joints and cooling water to a closed-type cooling tower.

- Note: Ensure the inlet water pressure is between 1.5 to 3.0 bar.

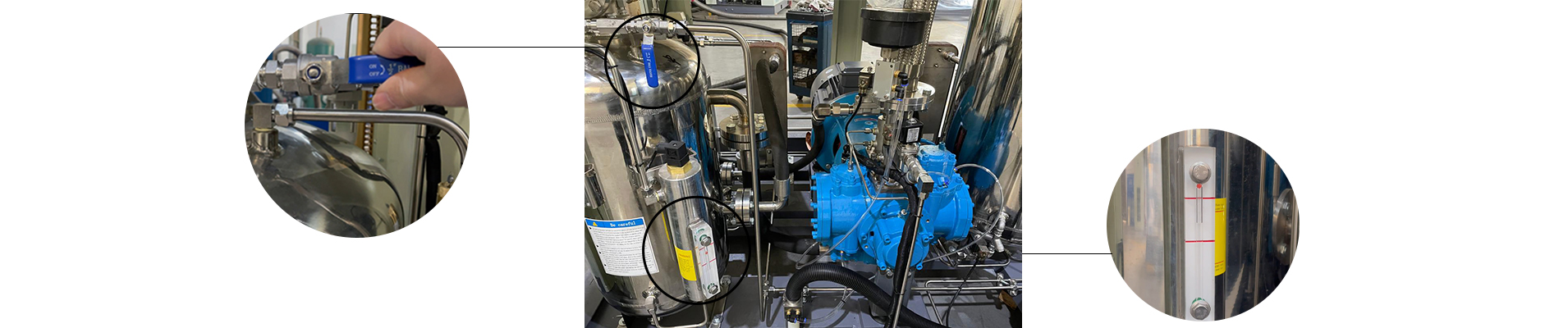

Step 4: Add Lubricating Water & Commissioning

- For the first-time filling:

- Manually open the water filling ball valve at the first stage and close it when the red ball in water level reaches the top red line on the gauge.

- Repeat the process for the second stage.

Step 5: Prepare for Startup and Check Components

- Once the electric, air, lubrication water, and cooling water pipelines are connected, double-check everything.

- Press the start button on the control panel to begin the compressor’s jogging or inching operations.

Jogging/inching operation explanation: Quickly press the start button several times to ensure the motor receives repeated starting and stopping commands in short bursts. This allows the motor to perform slow movements, preventing the air end (which is directly connected to the motor) from freezing under sudden high pressure, ensuring the air end is fully filled with the lubricating water.

- Ensure lubricating water circulates properly in the pipelines and reaches the air end.

- Confirm the motor rotation direction is correct and matches the marked indications.

Step 6: Start the Compressor

- After a final check, press and hold the start button for a few seconds and initiate full operation.

- Monitor the compressor for at least 30 minutes for any abnormalities.

- Once confirmed, the operator may leave as the machine runs smoothly.