Stainless Steel High Pressure Refrigerated Air Dryer SHAD Series

- Air Capacity: 6.5-85 [Nm³/min], 229.5-3000[cfm]

- Pressure Dew Point: 2-10 [℃], 35.6-50 [℉]

- Pressure Range: ≤4.0 MPa

- Inlet Air Temprature: ≤60 [℃], ≤172 [℉]

- Applicable Compressor Models: OGWBE

- Product Introduction

- Features

- Technical Specifications

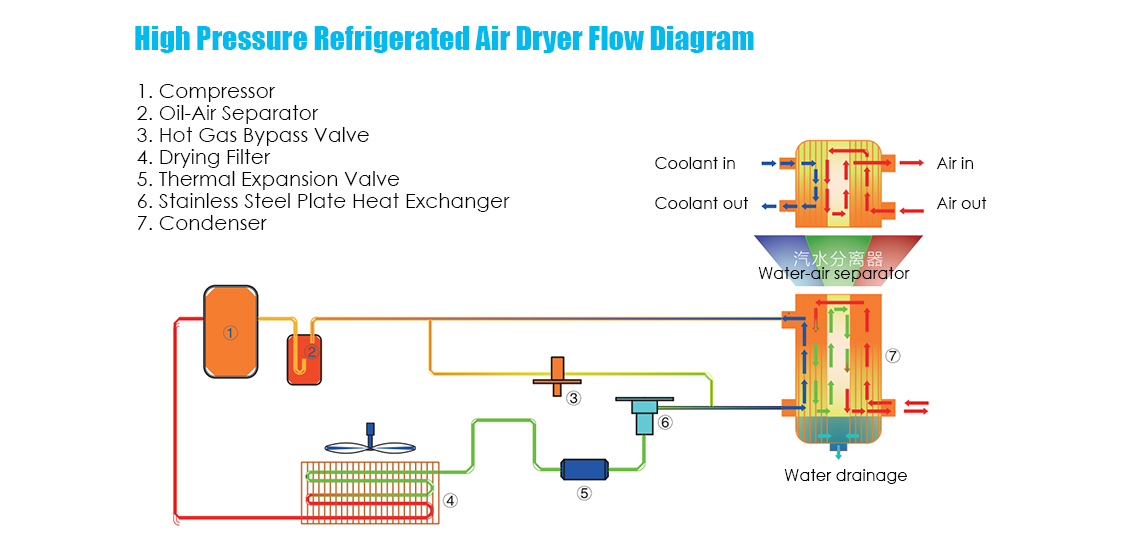

- Schematic Diagram

- Downloads

The high-temperature, high-humidity air compressed by the air compressor is pre-cooled using a stainless steel plate heat exchanger (combined three-in-one or two-in-one system). This system utilizes the dried, low-temperature air to cool the high-temperature, high-humidity air. The resulting medium-temperature, high-humidity air then enters the evaporator, where it is cooled by the low-temperature refrigerant, causing moisture to condense.

In the gas-water separator, centrifugal force and gravity are employed to separate the water from the dry air. Finally, the dried air passes through the pre-cooler (or reheater) to exchange heat with the high-temperature, high-humidity air before reaching the application end.

Durable and Reliable

- 304 stainless steel heat exchanger assembly & air connections prevent secondary contamination.

- Suitable for food, pharmaceuticals, electronics, and high-end coatings.

- Nano anti-corrosion coating on air-cooled condenser enhances durability.

Energy Efficient

-

- Plate type heat exchanger improves heat changing efficiency.

- A 3–5°C temperature difference at inlet and outlet of pre-cooler ensures low relative humidity and eliminates condensation.

- Pre-heater recovers over 90% of cooling energy, reducing energy consumption to 70% of similar products.

Safe and Reliable

-

- Equipped with multiple overload protection features.

- CE safety certification obtained for all products.

Frequently Asked Questions

The following are frequently asked by our customers about air compressor air dryer.

Our high pressure refrigeration air dryers handle air capacities ranging from 6.5 to 85 Nm³/min (229.5 to 3000 cfm), making them suitable for demanding industrial applications with large air volume requirements.

The pressure dew point range is between 2-10°C (35.6-50°F), providing dry air that minimizes moisture-related issues in high-pressure systems and ensuring product quality and equipment longevity.

Our high pressure refrigerated air dryers can operate at pressures up to 4.0 MPa, supporting applications requiring higher pressures, such as PET bottle manufacturing and industrial processes.

There’s basically no maintenance needed for our high pressure compressed air dryer because no consumable parts are inside.

Yes, our dryers incorporate energy-saving features, reducing operational costs by optimizing power use at low airflow levels, ensuring energy efficiency while maintaining a steady dew point.