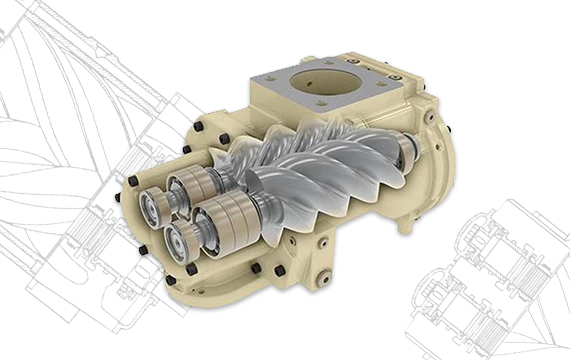

What is an Oil Lubricated Rotary Screw Compressor?

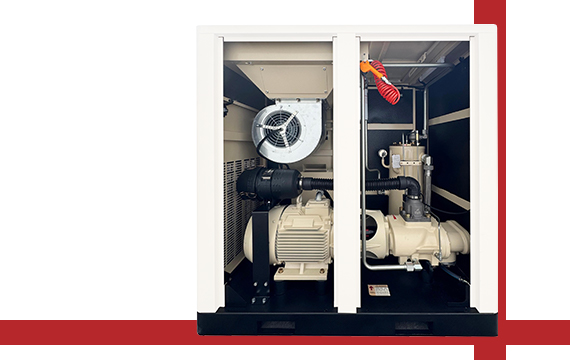

An oil-lubricated rotary screw compressor uses oil to seal, cool, and lubricate its internal components during compression. This design ensures efficient, continuous operation, making it ideal for industrial applications requiring high-duty performance.

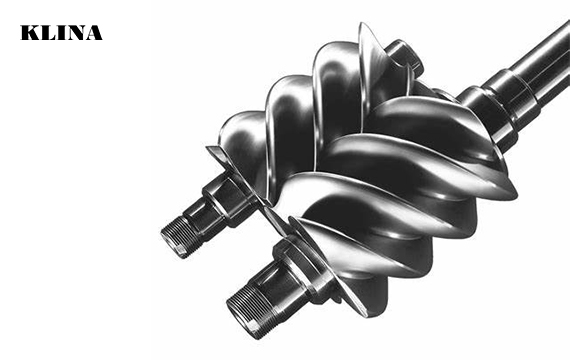

A rotary screw air compressor uses twin spiral screws to compress air through positive displacement. In oil-lubricated systems, oil fills the space between the helical rotors, creating an air-tight hydraulic seal and efficiently transferring mechanical energy. As atmospheric air enters the system, the interlocking screws push it through the compression chamber. The oil also cools, seals, and lubricates the internal components, reducing friction and minimizing air leakage. This design allows for continuous, high-performance operation with steady air flow, making it ideal for demanding industrial applications. With lower maintenance requirements and an extended lifespan, these compressors deliver reliable and energy-efficient performance.

Oil-Injected Rotary Screw Compressors

出力: 7.5~22kW

圧力: 0.8-1.6 MPa

FAD Capacity: 1.1-2.3 m3/min

圧縮段数:1

出力: 37~405kW

圧力: 3.0~4.0 MPa

FAD容量: 3.5-45.0 m3/分

圧縮段数:2~3

Industries That Use Rotary Screw Air Compressors

Features That Shape KLINA Ratory Compressors

Designed for optimal energy savings, Klina rotary screw compressors reduce energy and operating costs. With airends featuring 8-9 bearings in single-stage models and 20 bearings in two-stage models, they deliver exceptional efficiency.

Built with high-quality components, Klina rotary screw compressors ensure consistent performance and minimize downtime. Their robust design reduces maintenance costs, ensuring long-term reliability.

Klina rotary screw compressors are compact, making them ideal for industries with limited space. Their design allows for easy installation in various industrial environments.

Available in various capacities, Klina screw compressors cater to a wide range of industries, from manufacturing to construction and automotive, offering flexible solutions for different applications.

業界をリードするエアエンド

KLINAエアエンドは、シングルステージモデルには8~9個、ツーステージモデルには20個のベアリングを搭載し、卓越した効率と耐久性を実現しています。この先進的な設計により、要求の厳しい用途でも優れた性能を発揮し、エネルギー節約と動作信頼性を最大限に高めます。

Efficiency with Variable Speed

More efficient than piston compressors, rotary screw compressors offer superior performance while significantly reducing energy consumption. With Klina VSD compressors, they can adapt to real-time demand, thus lowering operational costs by up to 30%.

Robust Design

Rotary screw air compressors are built for durability, featuring lower maintenance requirements. They are designed to operate in both high and low-temperature environments, ensuring reliable performance in a wide range of conditions.

How Do Rotary Screw Air Compressors Work?

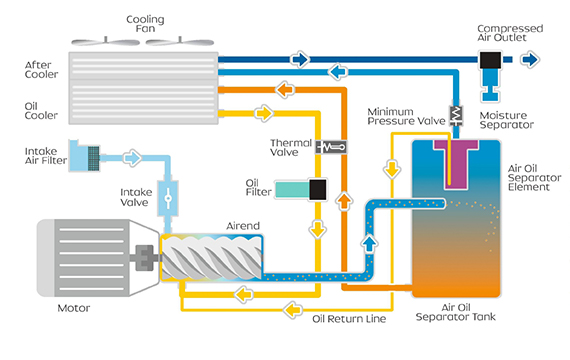

KLINA Oil-flooded rotary screw compressors operate by using two interlocking helical rotors that spin in opposite directions to compress air. As air enters the system, it fills the gap between the screw threads or grooves, where it is compressed as the screws rotate. The majority of rotary screw compressors are oil-flooded, where oil is used to seal, lubricate, and cool the compression process. However, oil-free screw compressors are also available for applications requiring contamination-free air.

- Air intake: Atmospheric air is drawn into the compressor through an intake valve.

- Rotor compression: Two interlocking helical rotors compress the air as they rotate.

- Oil injection: Oil is injected into the compression chamber, forming a seal and enhancing compression efficiency.

- 冷却: The oil absorbs heat generated during compression, cooling both the air and compressor components.

- Air-oil separation: After compression, the air-oil mixture is directed to an oil separator, where the oil is removed from the compressed air.

- Oil recirculation: The separated oil is recycled back into the system for reuse.

- Compressed air delivery: The purified, compressed air is then delivered to the air system for use.

Why KLINA Air Compressors?

KLINA, a complementary brand to GAIRS, provides both oil-injected rotary screw compressors and oil-free single screw compressors. These models offer economical and practical solutions for clients looking to meet their compressed air demands efficiently.

GAIRS と KLINA はどちらも GAIRS グループに属しています。GAIRS はハイエンドの圧縮空気市場をターゲットにしており、水注入式オイルフリー シングル スクリュー技術にのみ焦点を移しています。GAIRS の使命は、100% のクリーンな圧縮空気を提供しながら、すべての GAIRS コンプレッサーの地球温暖化係数 (GWP) を最低に抑え、より持続可能な環境に貢献することです。

KLINA は信頼できるパートナーと連携して、オイル注入式ロータリースクリューコンプレッサーと水注入式オイルフリーシングルスクリューコンプレッサーの両方を提供しています。これらのモデルは、クライアントの圧縮空気のニーズに効率的で経済的、かつ実用的なソリューションを提供します。

はい、OEM 注文も承ります。お客様の特定の要件に合わせて製品をカスタマイズいたします。設計、構成、その他の特別なリクエストなど、詳細な仕様をお知らせください。お客様のビジネスに合わせた最適なソリューションをご提供いたします。

はい、異なる圧力のコンプレッサーはページには表示されていませんが、いつでもメールでお問い合わせいただけます。

関連商品

あなたも知りたいかもしれません

KLINA ロータリースクリュー式エアコンプレッサーについて、お客様からよく寄せられる質問をご紹介します。

コンプレッサーに問題が発生した場合は、まず当社の営業担当者に連絡してリモートビデオガイドを入手してください。操作パラメータを勝手に変更しないでください。

ロータリースクリューコンプレッサーは、連続的な空気の流れを提供し、サイクルで動作するピストンコンプレッサーに比べてエネルギー効率が高く、メンテナンスの必要性が少なくなります。

VSD テクノロジーは、リアルタイムの空気需要に基づいてコンプレッサーのモーター速度を調整し、エネルギー消費と運用コストを最大 30% 削減します。

ロータリースクリューコンプレッサーは可動部品が少ないためピストンコンプレッサーよりもメンテナンスが少なく、摩耗も少なくなりますが、フィルター、オイル、その他の消耗部品の定期的なメンテナンスは必要です。

通常、ロータリーコンプレッサーのリードタイムは約 25 ~ 30 営業日です。