Variable Speed Air Compressors Lineup

Power: 7.5-250 kW

Pressure: 0.7-1.0 MPa

FAD Capacity: 0.9-43.0 m³/min

Number of compression stage: 1

Lubricant: RO Water

Power: 11-220 kW

Pressure: 0.3-0.4 MPa

FAD Capacity: 2.4-60.0 m³/min

Number of compression stage: 1

Lubricant: RO Water

Power: 92-352 kW

Pressure: 0.8-1.0 MPa

FAD Capacity: 20.0-60.0 m³/min

Number of compression stage: 2

Lubricant: RO Water

Power: 52-440 kW

Pressure: 3.0-4.0 MPa

FAD Capacity: 6.0-40.0 m³/min

Number of compression stage: 2

Lubricant: RO Water

Power: 7.5-250 kW

Pressure: 0.7-1.0 MPa

FAD Capacity: 0.9-43.0 m³/min

Number of compression stage: 1

Lubricant: RO Water

Power: 11-220 kW

Pressure: 0.3-0.4 MPa

FAD Capacity: 2.4-60.0 m³/min

Number of compression stage: 1

Lubricant: RO Water

Power: 92-352 kW

Pressure: 0.8-1.0 MPa

FAD Capacity: 20.0-60.0 m³/min

Number of compression stage: 2

Lubricant: Oil

Power: 52-440 kW

Pressure: 3.0-4.0 MPa

FAD Capacity: 6.0-40.0 m³/min

Number of compression stage: 2

Lubricant: Oil

Power: 7.5-250 kW

Pressure: 0.8 MPa

FAD Capacity: 1.1-45.5 m³/min

Number of compression stage: 1

Lubricant: Oil

Power: 15-315 kW

Pressure: 0.8 MPa

FAD Capacity: 2.8-66.0 m3/min

Number of compression stage: 2

Lubricant: Oil

Power: 7.5-22 kW

Pressure: 0.8-1.6 MPa

FAD Capacity: 1.1-2.3 m³/min

Number of compression stage: 1

Lubricant: Oil

Power: 37-405 kW

Pressure: 3.0-4.0 MPa

FAD Capacity: 3.5-45.0 m3/min

Number of compression stage: 2-3

Lubricant: Oil

How Do Variable Speed Air Compressors Work?

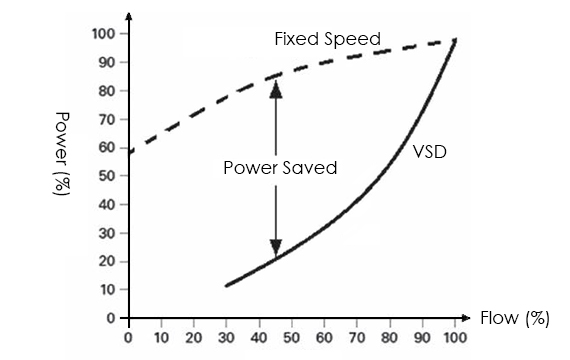

A Variable Speed Drive (VSD) compressor works by adjusting the speed of its motor in response to real-time demand for compressed air. This is achieved through an integrated VSD controller, which adjusts the motor’s rotational speed to match the required output. When demand is high, the motor runs faster to supply more compressed air; when demand drops, the motor slows down, producing only the necessary amount of air. This flexibility helps prevent unnecessary cycles, reducing energy waste and wear on the compressor.

How It Works Step-by-Step:

- Demand Sensing: The VSD controller monitors the system’s air requirements continuously.

- Motor Adjustment: Based on this feedback, it adjusts the motor speed accordingly, slowing it during low demand and increasing speed when demand rises.

- Continuous Modulation: Unlike fixed-speed compressors that toggle between on and off or idle modes, VSD compressors run only as needed, ensuring consistent pressure levels without excessive cycling.

How It Works with a PM Motor:

Our OGW and JLW oil-free series are all equipped with VSD+PM combo. Variable Speed Drive (VSD) technology integrates an Permanent Magnet (PM) motor in a direct-drive design, enhancing both energy efficiency and noise reduction. On average, compressors using PM technology lower energy consumption by up to 50% compared to standard idling compressors.

Both GAIRS and KLINA belong to the GAIRS Group. GAIRS targets the high-end compressed air market and has shifted its focus solely to water-injected oil-free single screw technology. GAIRS’ mission is to deliver 100% clean compressed air while ensuring every GAIRS compressor has the lowest Global Warming Potential (GWP), contributing to a more sustainable environment.

KLINA, in collaboration with trusted partners, offers both oil-injected rotary screw compressors and water-injected oil-free single screw compressors. These models provide efficient, economical, and practical solutions for clients’ compressed air needs.

Yes, we accept OEM orders. We are happy to customize our products to meet your specific requirements. Please provide detailed specifications, including design, configuration, and any other special requests, so we can offer the best solution tailored to your business.

Yes, though compressors with different pressure are not shown on the page, you can always give us an email for inquiry.

Related Product

You May Also Want To Know

The following are frequently asked by our customers about variable speed air compressors.

A VSD air compressor adjusts its motor speed to match real-time air demand, offering energy efficiency and reducing wear compared to constant-speed models.

By adjusting output to meet demand, VSD compressors avoid constant running at full capacity, cutting energy consumption significantly—often reducing energy costs by up to 50% compared to fixed-speed compressors.

Industries with fluctuating air demand, such as manufacturing, automotive, food and beverage, and pharmaceutical production, can see substantial energy and cost savings from using VSD compressors.

By matching motor speed to air demand, VSD compressors experience less wear and fewer start-stop cycles, which prolongs the compressor’s lifespan and ensures reliable performance over time.

Not necessarily. For industrial processes with consistent, stable air demand, a well-sized fixed-speed compressor can deliver compressed air reliably and efficiently. When demand varies only within 5-10% of the total free air delivery rate, a fixed-speed compressor may actually offer greater efficiency than a Variable Speed Drive (VSD) model.