Water-injected screw compressors, such as the OGW series, rely on pure water for lubrication, cooling, and sealing. Unlike traditional oil-lubricated compressors, these oil-free compressors use water as a natural coolant and lubricant, ensuring clean compressed air with high efficiency. However, to maintain optimal performance and extend the service life of the air end, using Reverse Osmosis (RO) water is crucial. This blog explains why RO water is necessary, the risks of poor water quality, and how to maintain a stable compressed air system.

Why Do Water-Injected Screw Compressors Require RO Water?

1. Water’s Role in a Water-Injected Oil-Free Compressor

In a water-injected screw compressor, water is continuously sprayed into the air end. It serves three key functions:

Cooling: Water absorbs heat generated during compression, keeping the air end temperature below 55°C—eliminating the need for an intercooler.

Lubrication: The water film reduces friction between the screw rotor and star wheels, ensuring smooth operation.

Sealing: Water fills the micro gaps between rotor grooves and star wheel teeth, improving the volumetric efficiency of the compressor.

Since this water is recirculated, its quality directly impacts the compressor’s efficiency, reliability, and lifespan.

2. The Importance of RO Water

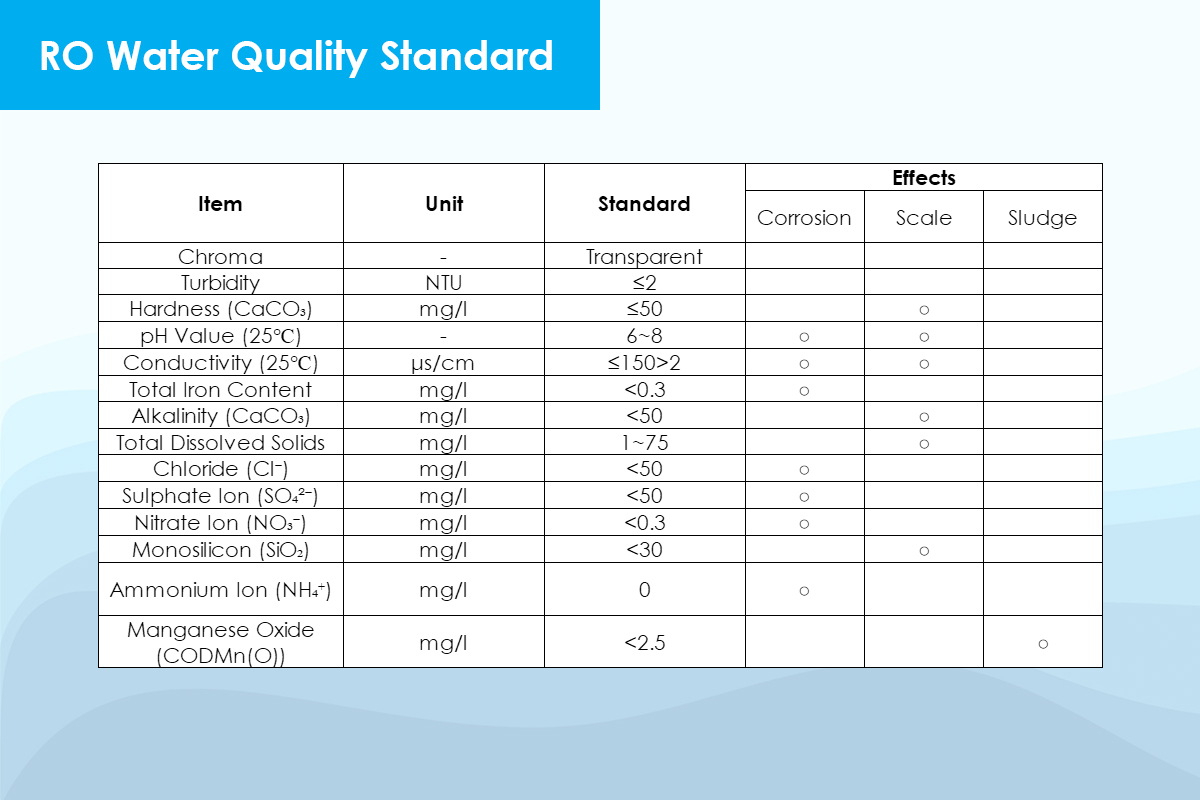

RO (Reverse Osmosis) water is purified water with minimal impurities, ensuring:

No Scaling: RO water removes calcium (Ca²⁺) and magnesium (Mg²⁺) ions, preventing scale buildup inside the air end, piping, and cooler.

Better Cooling Performance: Pure water has better heat absorption properties, improving overall cooling efficiency.

Extended Air End Life: Using hard water leads to corrosion, bacterial growth, and sludge accumulation, reducing compressor efficiency.

Stable System Operation: RO water minimizes clogs in water filters and prevents blockages that can reduce airflow and cause system failures.

3. Why a Water Softener Alone is Not Enough?

A water softener removes hard minerals like calcium and magnesium using an ion-exchange resin. However, it does not:

❌ Remove all salts and dissolved solids.

❌ Prevent bacterial growth in the water loop.

❌ Guarantee the required low conductivity for long-term compressor operation.

That’s why even with a water softener, the compressor still requires RO water to meet the strict quality standards necessary for long-term reliability.

Problems Caused by Poor Water Quality

If the water quality is not maintained, several issues can arise:

1. Scaling – The Silent Killer

Cause: Hard water contains high levels of calcium and magnesium, which form scale deposits inside the compressor system.

Effects:

- Reduces cooling efficiency.

- Causes higher internal temperatures, leading to premature wear of components.

- Blocks water pipes and heat exchangers, leading to pressure loss and inefficiency.

Solution: Use only RO water and replace the circulating water every two weeks in challenging environments.

2. Siltation – Clogging the System

Cause: Bacteria, dust, and fine particles accumulate in the water loop, forming sludge in the system.

Effects:

- Blocks water filters, requiring frequent maintenance.

- Increases the risk of bacterial contamination in the compressed air.

- Leads to higher pressure drop and reduced efficiency.

Solution: Regularly change water filters and ensure proper ventilation in the compressor room.

3. Corrosion – Shortens Air End Life

Cause: Impurities and dissolved salts leads to jam of air end.

Effects:

- Weakens internal components, leading to expensive repairs.

- Reduces the air end lifespan.

Solution: Monitor RO water quality regularly and replace it if contamination levels rise.

Cooling Water Requirements for Water-Cooled Models

For water-cooled water injected screw compressors, cooling water must also meet strict quality requirements:

✔️ Closed-loop cooling system recommended – to maintain stable water quality.

✔️ Cooling water pressure: 0.15-0.3 MPa.

✔️ Inlet water temperature: Should not exceed 32°C.

✔️ Water quality: Should meet the RO water standard to prevent scale buildup inside the heat exchanger and piping.

How to Replace Lubrication Water in a Water-Injected Screw Compressor?

To maintain the system, regularly replace the lubrication water using the following steps:

- Ensure the compressor is fully stopped and that the air and water separator is depressurized.

- Drain the existing water from the separator using the manual drain valve.

- Refill with fresh RO water using the manual water refill valve until the water level reaches the middle of the water level gauge.

- Restart the compressor and monitor the system to ensure proper operation.

Pro Tip: If the operating environment is poor (e.g., high humidity, exposure to acidic gases), shorten the water change cycle to prevent contamination and extend the air end’s service life.

Need RO Water? Get an RO Water Purifier

If your facility does not have access to an RO water source, we strongly recommend investing in a Reverse Osmosis (RO) water purifier. This ensures a consistent supply of high-purity water, protecting your compressor from scaling, corrosion, and performance loss. A properly maintained RO system will not only extend the lifespan of your compressor but also reduce operating costs in the long run.