Single Stage Air Compressors Lineup

Daya: 7,5-250 kW

Tekanan: 0,7-1,0MPa

Kapasitas FAD: 0,9-43,0 m³/menit

Jumlah tahap kompresi: 1

Pelumas: Air RO

Daya: 11-220 kW

Tekanan: 0,3-0,4 MPa

Kapasitas FAD: 2,4-60,0 m³/menit

Jumlah tahap kompresi: 1

Pelumas: Air RO

Daya: 7,5-250 kW

Tekanan: 0,7-1,0MPa

Kapasitas FAD: 0,9-43,0 m³/menit

Jumlah tahap kompresi: 1

Pelumas: Air RO

Daya: 11-220 kW

Tekanan: 0,3-0,4 MPa

Kapasitas FAD: 2,4-60,0 m³/menit

Jumlah tahap kompresi: 1

Pelumas: Air RO

Daya: 7,5-250 kW

Tekanan: 0,8 MPa

Kapasitas FAD: 1,1-45,5 m³/menit

Jumlah tahap kompresi: 1

Pelumas: Oli

Daya: 7,5-250 kW

Tekanan: 0,8 MPa

Kapasitas FAD: 1,1-45,5 m³/menit

Jumlah tahap kompresi: 1

Pelumas: Oli

Daya: 7,5-22 kW

Tekanan: 0,8-1,6MPa

Kapasitas FAD: 1,1-2,3 m³/menit

Jumlah tahap kompresi: 1

Pelumas: Oli

Daya: 7,5-22 kW

Tekanan: 0,8-1,6MPa

Kapasitas FAD: 1,1-2,3 m³/menit

Jumlah tahap kompresi: 1

Pelumas: Oli

How Do Single Stage Air Compressors Work?

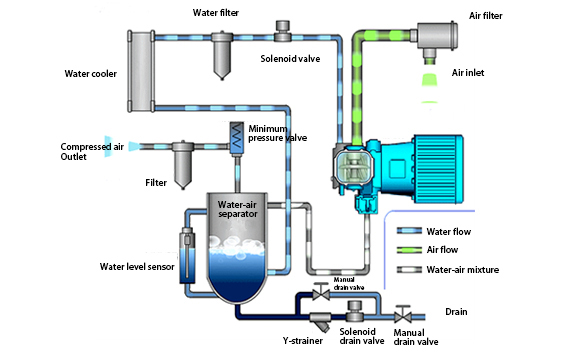

In oil-free water-injected screw models, single phase compressors use a rotating helical screw and two symmetrically placed star wheels to compress air. Water injected into the compression chamber absorbs heat, reduces friction, and seals gaps for higher efficiency. After compression, a separator tank divides air and water, with the air discharged and water recirculated within the system.

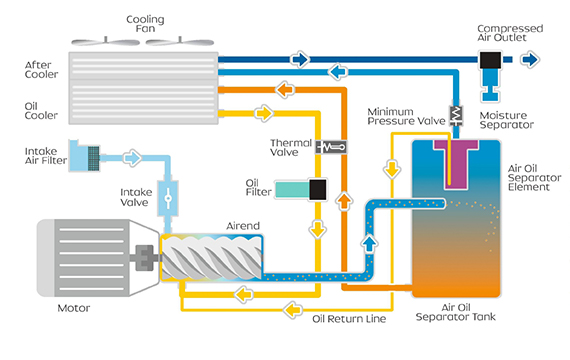

In oil-flooded screw models, single phase compressors operate by using two interlocking helical rotors that spin in opposite directions to compress air. As air enters the system, it fills the gap between the screw threads or grooves, where it is compressed as the screws rotate. The majority of rotary screw compressors are oil-flooded, where oil is used to seal, lubricate, and cool the compression process. However, oil-free screw compressors are also available for applications requiring contamination-free air.

Baik GAIRS maupun KLINA merupakan bagian dari Grup GAIRS. GAIRS menargetkan pasar udara bertekanan kelas atas dan telah mengalihkan fokusnya hanya ke teknologi sekrup tunggal bebas oli yang diinjeksi air. Misi GAIRS adalah untuk menghasilkan udara bertekanan bersih 100% sekaligus memastikan setiap kompresor GAIRS memiliki Potensi Pemanasan Global (GWP) terendah, yang berkontribusi pada lingkungan yang lebih berkelanjutan.

KLINA, bekerja sama dengan mitra tepercaya, menawarkan kompresor sekrup putar injeksi oli dan kompresor sekrup tunggal bebas oli injeksi air. Model-model ini memberikan solusi yang efisien, ekonomis, dan praktis untuk kebutuhan udara terkompresi klien.

Yes, we accept OEM orders. We are happy to customize our products to meet your specific requirements. Please provide detailed specifications, including design, configuration, and any other special requests, so we can offer the best solution tailored to your business.

Ya, meskipun kompresor dengan tekanan berbeda tidak ditampilkan di halaman, Anda selalu dapat mengirimi kami email untuk menanyakan.

Produk Terkait

Anda Mungkin Juga Ingin Tahu

The following are frequently asked by our customers about single stage air compressors.

A single-stage air compressor compresses air in one stroke, where atmospheric air is drawn into a cylinder and compressed to deliver at a set pressure, typically around 90-145 psi.

A single-stage compressor compresses air only once, while a two-stage compressor compresses air twice, achieving higher pressure and making it suitable for heavier industrial applications.

Single-stage compressors offer simpler design, lower initial cost, easy maintenance, and are generally more compact, making them a great choice for small businesses or DIY users.

For oil-injected compressors, regular maintenance includes checking oil (or water) levels, valves and other spare parts as well as cleaning and replacing filters. Proper maintenance extends the compressor’s lifespan and ensures consistent performance.

At Gairs, single-stage compressors typically reach up to 181 psi (12.5 bar), though some models may go higher to 232 psi (16 bar), depending on the application.