Single Stage Air Compressors Lineup

出力: 7.5~22kW

圧力: 0.8-1.6 MPa

FAD容量: 1.1~2.3 m³/分

圧縮段数:1

潤滑剤: オイル

出力: 7.5~22kW

圧力: 0.8-1.6 MPa

FAD容量: 1.1~2.3 m³/分

圧縮段数:1

潤滑剤: オイル

How Do Single Stage Air Compressors Work?

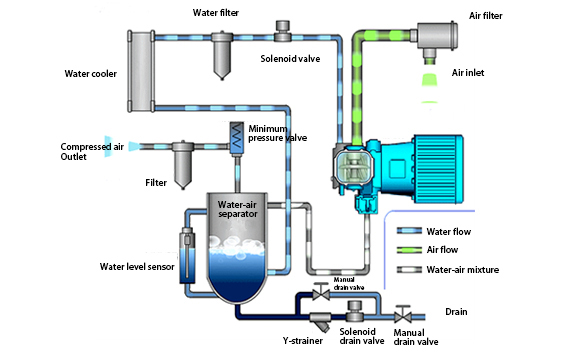

In oil-free water-injected screw models, single phase compressors use a rotating helical screw and two symmetrically placed star wheels to compress air. Water injected into the compression chamber absorbs heat, reduces friction, and seals gaps for higher efficiency. After compression, a separator tank divides air and water, with the air discharged and water recirculated within the system.

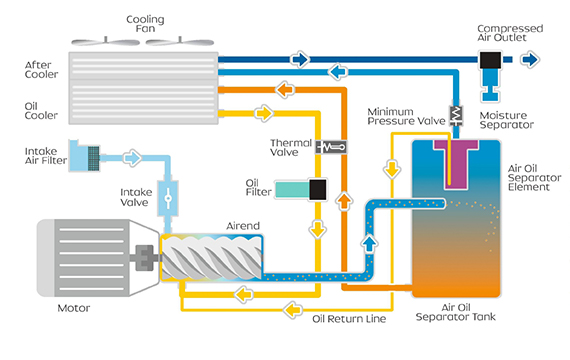

In oil-flooded screw models, single phase compressors operate by using two interlocking helical rotors that spin in opposite directions to compress air. As air enters the system, it fills the gap between the screw threads or grooves, where it is compressed as the screws rotate. The majority of rotary screw compressors are oil-flooded, where oil is used to seal, lubricate, and cool the compression process. However, oil-free screw compressors are also available for applications requiring contamination-free air.

GAIRS と KLINA はどちらも GAIRS グループに属しています。GAIRS はハイエンドの圧縮空気市場をターゲットにしており、水注入式オイルフリー シングル スクリュー技術にのみ焦点を移しています。GAIRS の使命は、100% のクリーンな圧縮空気を提供しながら、すべての GAIRS コンプレッサーの地球温暖化係数 (GWP) を最低に抑え、より持続可能な環境に貢献することです。

KLINA は信頼できるパートナーと連携して、オイル注入式ロータリースクリューコンプレッサーと水注入式オイルフリーシングルスクリューコンプレッサーの両方を提供しています。これらのモデルは、クライアントの圧縮空気のニーズに効率的で経済的、かつ実用的なソリューションを提供します。

Yes, we accept OEM orders. We are happy to customize our products to meet your specific requirements. Please provide detailed specifications, including design, configuration, and any other special requests, so we can offer the best solution tailored to your business.

はい、異なる圧力のコンプレッサーはページには表示されていませんが、いつでもメールでお問い合わせいただけます。

関連商品

あなたも知りたいかもしれません

The following are frequently asked by our customers about single stage air compressors.

A single-stage air compressor compresses air in one stroke, where atmospheric air is drawn into a cylinder and compressed to deliver at a set pressure, typically around 90-145 psi.

A single-stage compressor compresses air only once, while a two-stage compressor compresses air twice, achieving higher pressure and making it suitable for heavier industrial applications.

Single-stage compressors offer simpler design, lower initial cost, easy maintenance, and are generally more compact, making them a great choice for small businesses or DIY users.

For oil-injected compressors, regular maintenance includes checking oil (or water) levels, valves and other spare parts as well as cleaning and replacing filters. Proper maintenance extends the compressor’s lifespan and ensures consistent performance.

At Gairs, single-stage compressors typically reach up to 181 psi (12.5 bar), though some models may go higher to 232 psi (16 bar), depending on the application.